The H2-Agrar Project aims to identify the potential and perspectives of hydrogen usage in agriculture. (Image source: DLG)

Five winners of the ‘DLG-Agrifuture Concept Winner’, which recognises pioneering achievements in agricultural technology, were announced by The German Agricultural Society (DLG)

The jury, which consisted of independent international experts appointed by the DLG, selected the five winners from a shortlist of 10 candidates, who were honoured at the digital award ceremony held as part of the ‘AGRITECHNICA digital’ programme on 15 February 2022. DLG’s networking platform hosted the award ceremony which is available to view free on-demand.

Below is the list of the five winners:

Controlled row farming – a farming method with uniform row widths promotes biodiversity

By Amazonen-Werke H Dreyer SE & Co. KG in cooperation with AGRAVIS Raiffeisen AG and Schmotzer Hacktechnik GmbH

The concept of ‘controlled row farming’ is a new arable farming method for agriculture in which every crop-cultivation step is carried out in relation to a fixed row, offering yield optimisation despite lower use of fertilisers and pesticides. By cultivating crops in a fixed and uniform row spacing of 50 cm (grain in double rows) and including a row offset of 25 cm for positive crop rotation effects, both yield optimisation and maximum efficiency of farms inputs are achieved. The option of introducing companion planting between the rows of the main crop increases the value of the agricultural ecosystem, e.g. by reducing water evaporation and erosion.

Spot farming – for a holistic and sustainable crop production system

Joint development by Technische Universität (TU) Braunschweig; Johann Heinrich von Thünen Institute; and Julius Kühn Institute (JKI)

The ‘spot farming’ concept places the living and growth conditions of individual cultivated plants at the levels of the plant, the field and the surrounding countryside at the center through the in-depth observation by the farmer. On this basis, an attempt is made to optimise four points – to select optimal crops or varieties for the respective site conditions, to improve spatial and temporal management practices, to increase the efficiency of agrochemicals and to strengthen functional structures in the agricultural landscape.

Automated fruit picking system by Kubota Germany GmbH and Tevel Aerobotics Technologies

Harvesting machines use innovative combination of wired drones and corresponding solutions for logistics. The drones are equipped with wind compensation which ensures safe and efficient operation in most weather. Reaching almost every fruit, and harvesting without any bruising, the drones detect and grade the individual fruit in real time, enabling pre-sorting and selective harvest. Information is transferred to the logistics system, optimising this harvesting step. Levels of automation are offered, from a simple 'navigation system' for tractor driver transporting the bins to fully autonomous carries which places empty bins and collects full ones. The concept can be integrated into existing harvesting operations and work processes. Benefits: Less food waste and yield increase of 20%.

Integrated drift management by Bayer AG Crop Science Division

The integrated drift management concept is based on the reading of information on the spray drift tendency and buffer zones as well as distance control shown on the labels of pesticides. When the pesticide is poured into the sprayer the saved information is translated into an application map. At the same time, wind direction and speed are recorded in the field in real time. If required, drift-reducing spray nozzles are activated and buffer zones and distance control are maintained, all automatically. The system records and saves all activities including weather information.

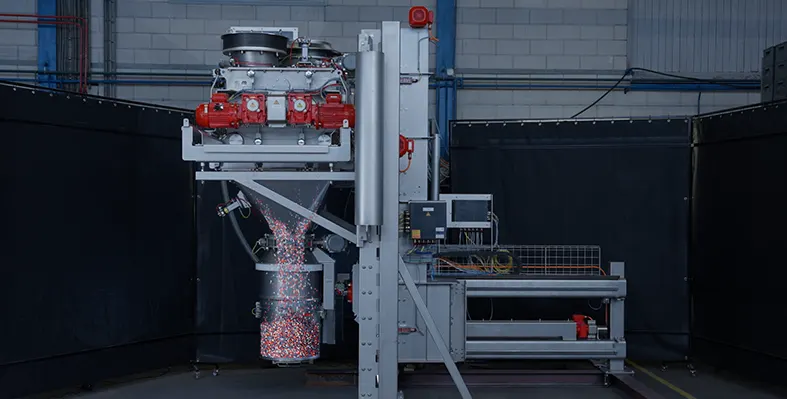

H2- Agrar Project by AGCO Fendt GmbH

In the context of the climate change debate, alternative concepts for mobility are at the top of the agenda. The H2-Agrar Project aims to identify the potential and perspectives of hydrogen usage in agriculture. Innovative solutions are underway showing not only that decentralised hydrogen production and use in agriculture can be economically successful but also how hydrogen-powered agriculture with a corresponding hydrogen infrastructure can be integrated into an overall system of hydrogen supply and ‘sector coupling’. In this way, questions about mobility can be processed using hydrogen-powered tractors and possible hydrogen mobility solutions can be demonstrated and tested. The concept also includes the transfer of local approaches and results to other agricultural areas.

“With this new concept award, the DLG is actively supporting pioneering ideas that lead the way to future global crop production. The new award focuses on the technical possibilities in the next five to 10 years and explores the realistic chances of implementation. We look forward to seeing more such future concepts at Agritechnica in 2023, which is the perfect platform for agricultural machinery innovations,” explained Florian Schiller, project manager, Digital Agriculture, DLG.