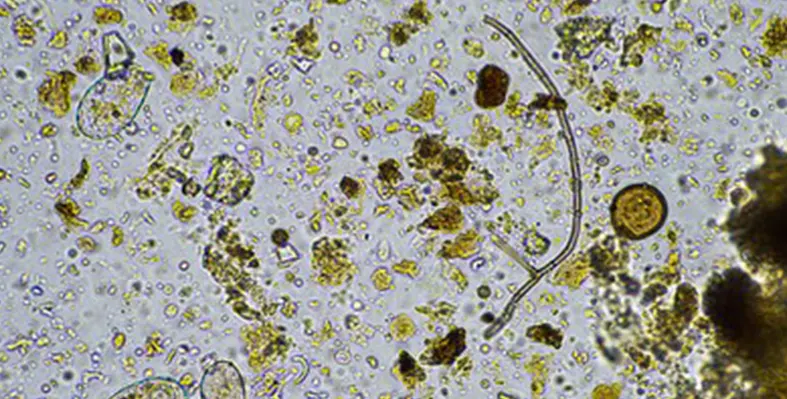

Moa's agreement with NAICONS gives the former exclusive rights to develop any new herbicides discovered in the library. (Image source: Moa Technologies)

Oxford-based agricultural biotech firm, Moa Technology has entered a partnership with Italian natural products company, NAICONS to find a safe, effective and affordable biological herbicide

With over 273 species of weeds that are now resistant to one or more commercially available herbicides, the need for new herbicides has never been more urgent. To date, Moa's platforms have screened almost 800,000 synthetic and naturally-occurring compounds, discovering over 70 potentially novel mode of action herbicides. Three synthetic herbicides with novel modes of action discovered by Moa have already performed strongly in their first two seasons of international field trials.

Moa's agreement with NAICONS gives the former exclusive rights to develop any new herbicides discovered in the library, with value to be shared from future licensing and commercialisation. CEO of Moa Technology, Dr Virginia Corless said the company is looking forward to applying the screening technology to NAICONS' high-quality library of actinomycete bacteria to find out whether a sustainable and effective biological compound can be discovered to assist farmers with controlling weeds.

"We are very excited about this collaboration," said NAICONS CEO, Stefano Donadio. "Our library has never been screened for herbicides and we are confident promising lead molecules will be rapidly identified through our powerful micro4all platform. Over 150,000 different molecules have been identified in the extracts sent to Moa and our team is eager to help in identifying the most promising herbicide candidates."