Leading precision agriculture designer, manufacturer and distributor, Topcon Agriculture recently announced the launch of its latest feeding system, TMR Flex Pro that enables smooth management of the feeding process

The system also provides real-time insight in key aspects such as dry matter, refusals and pen deliveries. Besides accuracy, other key elements that are critical to this include elements such as time and flexibility. This is particularly important for larger farms. Developed together with farmers, the modular TMR FlexPro helps improve daily workflow on the go and in a practical and convenient way.

A major advantage of this system inclues its self-explanatory interface which is simple and reduces the learning curve, while also ensuring ease of use for individual operators and feeding teams. Moreover, the system also allows multiple users to seamlessly collaborate during the loading and delivery process, thereby enhancing not only visibility, but also efficiency and productivity.

“Ingredient tracking functionality enhances inventory control, and the system’s unique refusal recording and substitution feature reduces feed waste, improving sustainability and farmers’ return on investment,” said Topcon Agriculture's senior vice president and segment leader of nutrition and weighing technologies, Wim De Wit.

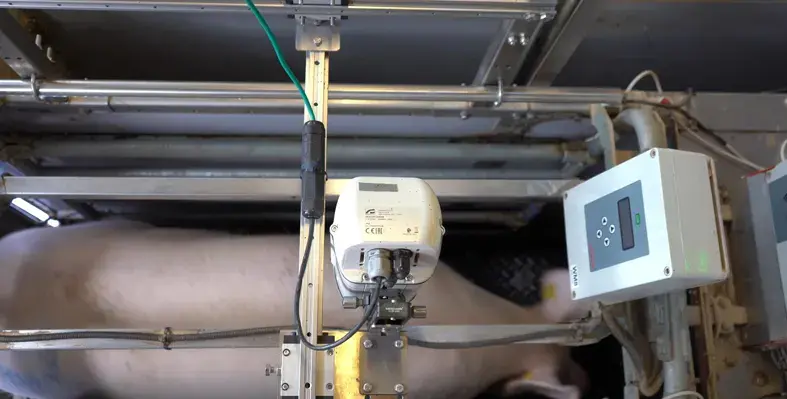

The system comprises the Digi-Star FD1 tablet, a data transfer device, and the TAP FEED Pro/Feedlot subscription and is designed to maximise efficiency in feed management, allowing producers to reduce costs and optimise resource utilisation. It offers enhanced data visibility and monitoring capabilities, providing farmers with valuable, data-driven insights for better planning and decision-making.

“TMR Flex Pro can be connected to existing Digi-Star scale systems or load cells of any kind on any brand feed mixer. It is the best-in-class upgrade solution to achieve a next-level feed management experience on any type or size dairy and feedlot operation,” De Wit said. “The TAP FEED cloud platform allows producers to collaborate with their trusted partners such as feed suppliers, nutritionists, and others who all have an increasing need for real-time data for the benefit of their advancing business models and sustainability agendas.”