Announcing the global release of the innovative temperature and vibration management (TVM) system for milling, Buhler provides essential information on the grinding process based on Buhler’s proprietary algorithms

As the system is connected to the Buhler Insights platform, TVM detects critical operational conditions early so millers can take timely action. Accurate management of the grinding process helps maintain the best product quality and consistency. Precise settings reduce energy consumption and product wastage. The launch of TVM represents another significant step towards the fully digitalised and automated smart mill.

Johannes Wick, CEO Grains & Food at Buhler, said, “Our digital services in combination with our industry expertise lift efficiency to entirely new levels and help millers and plant managers to further improve their mill’s performance. Until now controlling the grinding process has been very demanding and challenging. With Buhler’s Temperature and Vibration Management we know precisely what goes on in this important process.”

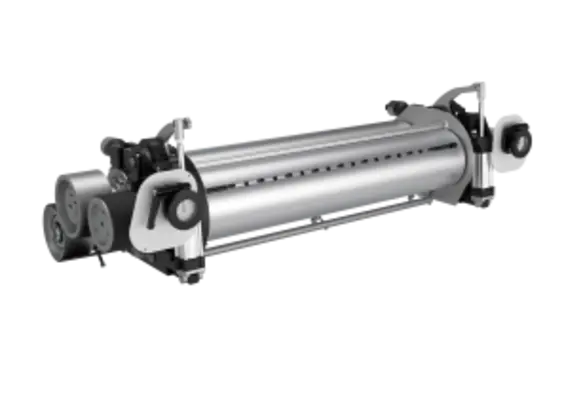

The new technology monitors temperature and vibrations inside the grinding rolls, the most important part of machinery in the milling process. To maintain quality and consistency it is essential to apply the same pressure along the rolls. Any deviation results in reduced quality and consistency of the flour. With Buhler’s TVM, millers can rely on accurate measurements to adjust any imbalances in the grinding gap.

The system consists of wireless sensors placed inside the rollers that connect to the Buhler IoT sensing device. It acts as the interface to the Buhler Insights gateway, which transfers data to the Buhler Insights platform for analysis. Temperature and vibration are measured at multiple points along the entire length of the rollers showing the temperature distribution and vibration patterns. The process can be monitored remotely via a user-friendly interface on any device.

On TVM installation at Willi Gruninger AG, Switzerland, Philipp Marquart, head of Foodstuff, said, “With TVM in place, it’s much easier to check the process and ensure that all parameters are set correctly. We have a much deeper insight in the process. We were able to increase grinding efficiency, improve product quality and reduce energy consumption. Our staffs are present at the mill for eight hours a day, but our machines keep running for another 16 hours. Whenever parameter tolerances are exceeded, personnel are alerted via the remote system and adjustments can be made from the comfort of their home.”