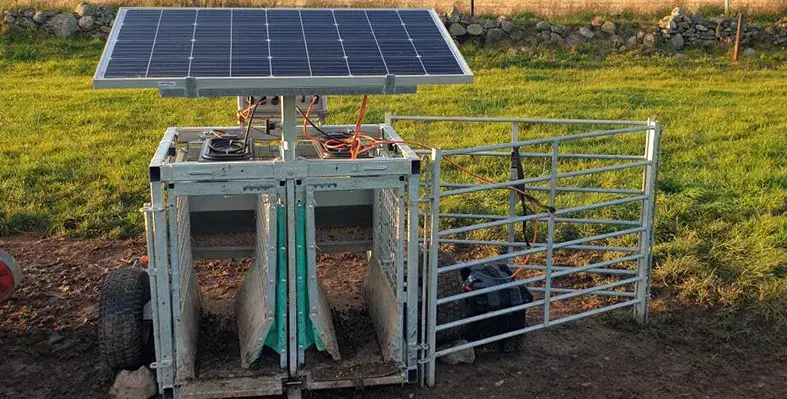

The platform enables more frequent datasets to be gained with no additional stress. (Image source: UK Agri-Tech Centre)

Following a partnership between David Ritchie (Implements) Ltd and the UK Agri-Tech Centre, a project, named ‘Lamb Monitor’, was created that aims to measure and monitor lamb performance, reduce farmers’ labour time and protect the welfare of lambs during the weighing process

The partners recognise that one of the most essential tasks involved in the production of lamb is the weighing of growing lambs in order to monitor their liveweight gain and suitability for sale. However, this is a time-consuming process and can be stressful to the lambs being gathered and weighed. Traditionally, weighing is carried out as often as once a fortnight, meaning the gap in daily live weight gain is not being monitored.

The platform enables more frequent datasets to be gained with no additional stress. Such data would allow lamb producers to monitor growth rates, enabling advanced and accurate predication of lamb sales as well as providing information with which to alter feeding, grazing and breeding management. In order to turn lamb weighing into a less stressful and time-intensive activity, this project aims to design, prototype and validate on-farm an automated, in-field lamb weighing solution.

Three different designs will be evaluated, with a walk-over weigher, creep feed attractant and climb on platform designed to utilise a lamb’s play instinct, with a data-handling app being developed alongside which will work with all three designs. The project will also develop a metered feed creep system, which prevents the dominant animals getting more than their share of feed and provides a restriction on intake of feeds which could cause ill-health if over-fed.

Using one of Ritchie’s trial farms and three of the UK Agri-Tech Centre’s satellite farms, Ritchie will construct initial prototypes for each design of weigher and commission them on-farm for validation. Farmers will continue to weigh their lambs as they currently do, with data gathered from this and the auto-weighers being compared to gain insights into the reliability and value of the data gathered from the auto-weigher, versus conventional weighing practice by the UK Agri-Tech Centre’s data and automation team.

Lamb weight data will also be carried through to Ritchie’s existing auto-drafting equipment to allow for lambs with sufficient weight data to be drafted automatically, reducing lamb stress and operator time at drafting. Lifecycle assessment will be used to examine the differences in carbon intensity between lamb systems with and without auto-weigher solutions to quantify the difference high-resolutions Daily Live Weight Gain monitoring may bring.

Charlie Brown, product development manager at Ritchie, said, “We hope to bring some level of automation and improved efficiency to the sheep industry with this product. The first prototype was created after farmer-led interactions resulted in us making efficiencies within the industry. Following field trials and farmer feedback we are refining the product for our Mk2 trial of the prototype.”

Hayley Gerry, project manager at the UK Agri-Tech Centre, said, “This project has enabled the UK Agri-Tech Centre to bridge a gap that the industry has identified where efficiencies could be made. Using our farmer network, we are able to test and validate the prototypes in a commercial set up to allow for feedback from the farmers. This will allow Ritchie to commercialise a product that will make farming more efficient.”

Research conducted by CIEL in 2020 showed how using measures such as data capture and use can have significant impact on Green House Gases (GHG) intensity of lamb production.

By finishing lambs at a younger age and reducing age at first lambing, amongst other factors, two hill farms had a 68% and 49% reduction in GHG emissions (kgCO2e/kgLW), and a lowland farm showed a reduction of 37% using these measures. In addition, Morgan-Davis et al (2018) estimated that precision livestock farming (PLF) tech can save farmers between 19% and 36% labour depending on the farm.

This study did not include an auto-weigher, rather just performance recording using electronic identification and software packages. The ability to use a lamb-monitor to expand on this will only add to the savings PLF tech can afford. With regard to welfare, the sheep weigher will significantly reduce the time requirement for farmers by not having to gather and weigh regularly, allowing them to better use their time either on other needs in the enterprise or to help improve the work life balance of farms and farm workers.

Improved animal welfare is achieved through less gathering and handling of sheep, ensuring a higher welfare food product is produced at the end as well as reducing the inherent risk in livestock handling to the farmers.