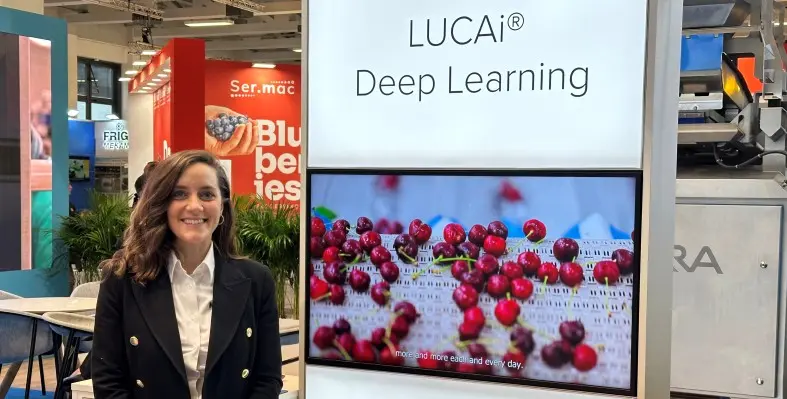

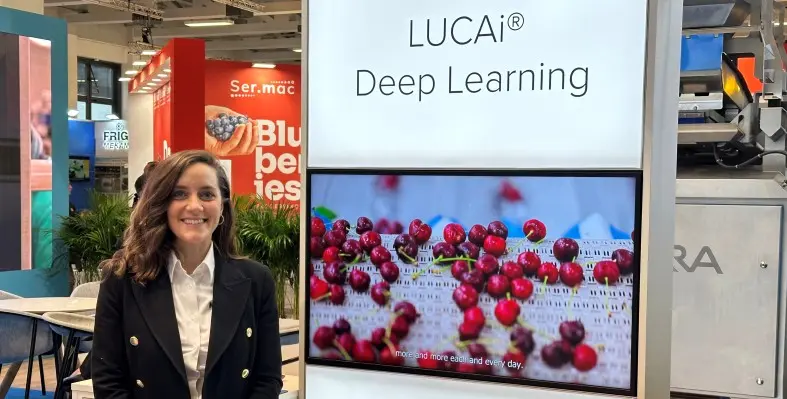

Global category director – Cherries at TOMRA Food, Benedetta Ricci Iamino. (Image source: TOMRA)

After one full season with TOMRA LUCAi, three cherry growers who installed the technology confirmed that they benefitted from higher productivity; enhanced quality selection with consequent higher margins for their customers; along with reduced food waste

In 2023, TOMRA Food was in the final stages of development of its AI-powered LUCAi platform, ready to trial its innovation with customers in different conditions and regions – from California to New Zealand. After the 2023 cherry season, Prima Frutta decided to install LUCAi on all of their machines, for a total of 132 lanes for their upcoming 2024 cherry season.

Moreover, two long-standing customers–Dunstan Hills and Panmure Orchards–who have been running TOMRA equipment for almost 10 years, were also keen to implement the TOMRA LUCAi technology. The three cherry growers shared the challenge of meeting the growing demand, with consistent high-quality produce, in the short cherry season, which typically begins in mid-May and finishes at the end of June in California, while in New Zealand it runs from early to mid-December to late January.

“With LUCAi we achieved better grading and increased throughput of around 10% – and it is easy to use,” said Ian Nicholls, operations manager at Dunstan Hills, after one full season with TOMRA LUCAi.

LUCAi's user-friendly interface software makes it very easy for the customer’s operators to get the best sorting and grading performance from their processing line. Founder of Prima Frutta Packing, Tim Sambado explained that the technology not only allowed them to make changes, but also provided them with accurate data on how it was going to impact their grading before the change was applied. Nicholls also agreed that the technology made it significantly easier for the operator to refine decision-making and improve grading. This not only helps cherry packers deliver consistent quality and meet the specific requirements of their customers, but it also enables them to increase their productivity and address the short cherry season.

The technology for the InVision2 cherry grading platform is unique unique in that it comes with vast amounts of data collected by TOMRA in different regions across the world, building pre-trained models using real images of cherries. This means that it is ready to deliver its superior sorting and grading performance as soon as it is installed. It uses TOMRA’s Deep Learning technology to identify with unparalleled accuracy an extensive range of defects – from edge cracks, Pacman cherries, open sutures, cosmetic blemishes and stem pulls, to spurs, cracks and all defects around the stem; from dehydration to apical splits; and it will recognise colours in the ripe phase with precision.

Moreover, the platform also continues to evolve as it keeps learning from the data it collects while running in the customer’s operation, future-proofing their business. TOMRA’s service team remains at their side after installation, ready to proactively help them optimise their sorting and grading performance.

“Thanks to LUCAi, the era of compromise is a thing of the past for our customers,” summarised global category director – Cherries at TOMRA Food, Benedetta Ricci Iamino. "The commitment is crystal clear – our customers can now confidently expect their best fruit, in prime condition, reaching optimal markets, all at highly competitive prices."

For more information, visit: www.tomra.com