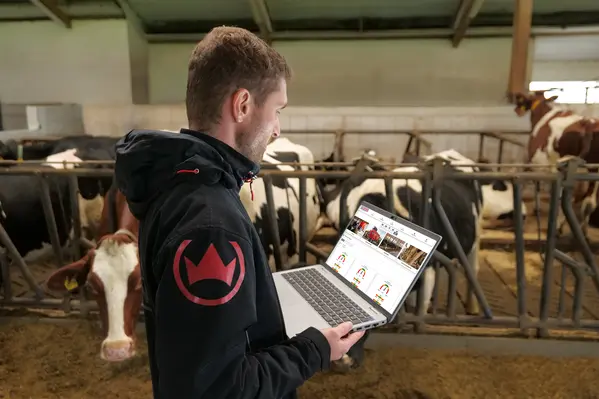

Agriculture AI company FarmVisionAI has introduced a new mobile app designed to engage growers in-field with vision AI stress detections

The mobile app brings FarmVisionAI’s horticulturist trained AI to a smartphone platform that can be used while scouting plants and walking the farm.

Location-specific information allows the grower and FarmVisionAI to validate the detections and complement the close-up images taken with the phone camera. The photos of the grower are geo-tagged to the location and appear in the desktop application that shows the grow in a ‘Google-earth’ like visualisation. To add value and explain what is happening in progress and what needs to be done, notes, recommendations, and actions can be applied to the imagery.

“The FarmVisionAI mobile app is a critical piece of functionality that bridges the gap between growers and operators,” said Jeff Bisberg, Illumitex CEO. “Our real-time imagery is the ground truth and provides transparency that can cut through communication barriers and finger-pointing.”

“Growing at scale can be extremely complex. The ability for FarmVisionAI users to capture images of specific issues through the mobile app is huge,” said Mark McDevitt, FarmVisionAI horticulture science leader. “First, the pictures are stored securely and organised in the FarmVisionAI system instead of the grower’s phones. Second, it makes it possible to analyse and diagnose individuals from anywhere in the world. And thirdly, it is an intellectual property repository in the form of visually based knowledge, specific to that site, which can be used for training, benchmarking and SOPs.”