In The Spotlight

Plukon has worked on minimising false rejections and ensuring the highest levels of metal detection by implementing Mitus from Minebea Intec. (Image source: Minebea Intec)

Detecting metals in poultry production with Minebea Intec's Mitus

To address the challenge of metal detection in poultry production, Plukon, a leading player in the poultry supply chain, has implemented the metal detector Mitus from Minebea Intec

Metal detection is a critical aspect of food safety protocols, especially in environments where contamination risks are high. However, traditional metal detectors often struggle to accurately detect metallic foreign objects in poultry products due to their unique electromagnetic properties. This not only causes product wastage, but can also have a major impact on food safety.

To combat these challenges, Plukon has worked on minimising false rejections and ensuring the highest levels of metal detection by implementing Mitus from Minebea Intec. Equipped with MiWave technology, Mitus works by significantly improving detection accuracy and reducing false rejects. By detection even the smallest metallic contaminants with unparalleled accuracy, the technology helps in overcoming the limitations of traditional metal detectors.

Moreover, the new design eases frequent cleaning procedures, which are essential and rigorous in this environment. Mitus also ensures compliance with HACCP standards, providing peace of mind to both Plukon and their customers regarding the safety and quality of their poultry products.

"We’ve faced many challenges with false rejects over the past few years, so I’m really pleased to have these new metal detectors on our lanes," said maintenance manager, Jeroen V. "They not only save us time and reduce costs, but also allow my hardworking team to stay focused on what truly matters.”

GEA Direct Sprayer DS 25 delivering powerful cleaning performance with five kilograms of spray force and a full-cone jet reaching up to five metres. (Image source: GEA)

GEA unveils new patented spray technology for tanks with agitators

GEA has introduced its new patented technology – the GEA Direct Sprayer DS 25 – for industrial tank cleaning in the food and beverage industry

The patented spray technology effectively removes residues from the undersides of agitators, pipes, and flow breakers. It has been developed for use in the beverage, food, dairy, pharmaceutical, and home and personal care industries, and is particularly advantageous in production environments with frequent recipe changes, strict hygiene standards, and demanding cleaning requirements.

In the food and beverage industry, cleaning tanks with internal installations often go through a major challenge. The undersides of agitator blades being in the spray shadow, prevents them from being adequately cleaned by conventional methods. This is where the Direct Sprayer DS 25 comes into picture. This technology sprays directly onto the undersides of the agitator blades while ensuring that the agitator mechanics remain unaffected. The cleaner is flush-mounted into the tank wall and can be positioned flexibly, ensuring full coverage inside the tank. The patented valve disc only opens when activated, ensuring an even distribution of the cleaning fluid. Since the valve plate opens inward, it does not interfere with the agitator.

The mechanically powerful full-cone spray targets the undersides of the agitators and efficiently removes residues. While conventional cleaning systems operate at lower forces, the GEA Direct Sprayer DS 25 operates with a spray force of up to 5 kg, allowing it to remove even tough residues. A case study from yogurt production has revealed the ability of the GEA Direct Sprayer DS 25 technology to reduce water usage by 84.5% and cleaning time by 87.5%, making it one of the most efficient cleaning methods for tanks with agitators.

“This time saving can be directly used for additional production capacity,” explained product sales manager for Cleaning Technology at GEA, Jana Zimpel. “In yogurt production, for example, this means more batches per day or faster recipe changes without compromising efficiency.”

Agmatix and BASF collaborate to develop SCN detection tool

Leading AI-powered solutions provider, Agmatix recently announced a strategic collaboration with BASF, one of the world’s largest chemical and agricultural solutions companies, to develop a cutting-edge digital solution aimed at detecting and predicting the presence of soybean cyst nematode (SCN)

The collaboration began through AgroStart, an open innovation and partnership platform by BASF, that aims to empower soybean growers with real-time, scalable insights to mitigate yield losses caused by SCN, one of the most damaging and often invisible soybean pests. Axiom, an advanced AI technology engine developed by Agmatix is the core of this initiative. It transforms vast amounts of raw agronomic data into highly standardised and enriched datasets. This rigorous data process enables the development of a robust machine-learning model capable of detecting and predicting SCN infestations with unprecedented accuracy and scalability.

Developed through AgroStart by BASF, this initiative combines Agmatix’s AI-driven agronomic platform with the deep expertise of BASF in seed and crop protection solutions and will foster the development of a scalable, user-friendly digital model. The tool will integrate with existing farm management practices, enabling users to access near real-time SCN risk assessments and tailor their pest management strategies accordingly.

SCN remains the leading pest in soybeans, with infestations frequently going undetected until yields are significantly affected. Traditional detection methods, such as soil sampling or mid-season root digs, are time-consuming, labour-intensive and not widely adopted. A digital tool could help create awareness and compliment these traditional methods.

By providing accurate, predictive data on SCN infestations, the Agmatix-BASF collaboration paves the way for future innovations in pest management and digital agriculture. The joint effort represents a significant leap forward in integrating digital agriculture with crop protection strategies, demonstrating how advanced analytics can drive on-farm decision-making and improve agronomic outcomes.

“Our collaboration with BASF is driven by the urgent need to provide a practical, data-backed tool that helps growers minimise yield losses caused by SCN,” added Ron Baruchi, president & CEO at Agmatix. “By digitising large volumes of field trial data within Axiom, we believe our machine learning model will give growers the power to act before SCN causes irreversible damage.”

Manila, Philippines

Ifigenia Urbina Barreto, PhD in Ecology and former Biome Makers employee conducting a tomato trial. (Image source: Biome Makers).

Collaboration demonstrates POLY4's impact on soil health

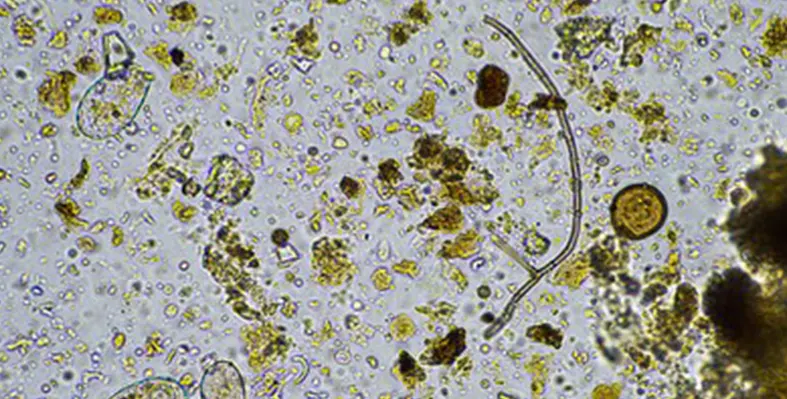

Biome Makers and Anglo American have collaborated on a joint research project on the impact of POLY4, Anglo American’s new low-carbon fertiliser, on the soil microbiome

The partnership involves soil trials that analyse and verify the impact of POLY4, Anglo American’s multi-nutrient fertiliser, on soil microbiome composition and functionality through a study on tomatoes and wheat in Spain.

Soil trials have confirmed that with a targeted approach, POLY4 is environmentally friendly and preserves native soil microbiome biodiversity and boosts microbial nutrient mobilisation of potassium (K), calcium (Ca), and chlorine (Cl), improving plant nutrient uptake and development. The research also showed a reduction in soil electrical conductivity, thanks to the activation of calcium and chlorine microbial mobilisation, which further supports healthy soil ecosystems.

“Our collaboration with Anglo American shows our commitment to advancing sustainable agriculture through applied science,” said Dr Alberto Acedo, chief scientific officer of Biome Makers. “By leveraging BeCrop’s proprietary microbiome analysis tools and global soil database, we are able to provide companies like Anglo American with strong evidence of the positive effects of emerging ag input products on soil health.”

Plukon has worked on minimising false rejections and ensuring the highest levels of metal detection by implementing Mitus from Minebea Intec. (Image source: Minebea Intec)

Detecting metals in poultry production with Minebea Intec's Mitus

To address the challenge of metal detection in poultry production, Plukon, a leading player in the poultry supply chain, has implemented the metal detector Mitus from Minebea Intec

Metal detection is a critical aspect of food safety protocols, especially in environments where contamination risks are high. However, traditional metal detectors often struggle to accurately detect metallic foreign objects in poultry products due to their unique electromagnetic properties. This not only causes product wastage, but can also have a major impact on food safety.

To combat these challenges, Plukon has worked on minimising false rejections and ensuring the highest levels of metal detection by implementing Mitus from Minebea Intec. Equipped with MiWave technology, Mitus works by significantly improving detection accuracy and reducing false rejects. By detection even the smallest metallic contaminants with unparalleled accuracy, the technology helps in overcoming the limitations of traditional metal detectors.

Moreover, the new design eases frequent cleaning procedures, which are essential and rigorous in this environment. Mitus also ensures compliance with HACCP standards, providing peace of mind to both Plukon and their customers regarding the safety and quality of their poultry products.

"We’ve faced many challenges with false rejects over the past few years, so I’m really pleased to have these new metal detectors on our lanes," said maintenance manager, Jeroen V. "They not only save us time and reduce costs, but also allow my hardworking team to stay focused on what truly matters.”

Monarch MK-V tractor demonstrating V2G through Borg Warner DCFC and Gridtractor CMS. (Image source: Gridtractor)

Monarch Tractor leads V2G revolution in agriculture

Gridtractor, Monarch Tractor, and Borg Warner have achieved a significant milestone by successfully demonstrating Vehicle-to-Grid (V2G) capabilities utilising a Monarch MK-V tractor, a Borg Warner 60 kW DC fast charger, and Gridtractor’s cloud-based charge management system employing the Open Charge Point Protocol (OCPP)

The latest additions to Alfa Laval’s valve portfolio demonstrate their commitment to meeting the evolving needs of industries where safety, efficiency and reliability are paramount. (Image source: Alfa Laval)

Alfa Laval strengthens hygienic valve portfolio

Alfa Laval has broadened its range and reaffirmed its commitment to providing reliable, high-performing solutions that ensure safe processing, protect product integrity, and safeguard consumers while addressing the evolving needs of the hygienic industries

The company has introduced the Unique SSV Pressure Relief Valve and the Leakage Detection Butterfly Valve, alongside new smaller sizes of the Unique Mixproof CIP and Unique Mixproof Process valves.

Unique SSV Pressure Relief Valve

When peak performance under pressure is critical, the Unique SSV Pressure Relief Valve protects hygienic processing lines, particularly those with positive displacement pumps, from overpressure. Paired with and powered by Alfa Laval ThinkTop technology for valve monitoring and control, it safeguards process efficiency, productivity and safety. Pressure relief setpoints are easy to adjust onsite to accommodate changing conditions. Built on the proven SSV platform, this modular valve shares spare parts with other Unique SSV valves, simplifying maintenance and reducing service costs. Fully CIP-able regardless of the pressure setting, the valve ensures reliable hygiene and performance while minimising downtime.

Leakage Detection Butterfly Valve

Product safety and efficiency are the hallmarks of this straightforward Leakage Detection Butterfly Valve. When powered by an Alfa Laval ThinkTop for valve monitoring and control, it enhances reliability due to real-time valve monitoring and control. Integrated leakage detection enables rapid response to potential issues, maintaining performance. A single seal, disc and actuator make the valve compact and lightweight while reducing installation, operating, and maintenance costs. Fully CIP-able, the valve guarantees more uptime, continuous operations, long-lasting performance, and energy, water and cleaning media savings.

Alfa Laval is also extending its Unique Mixproof range with two new sizes of the Unique Mixproof CIP and Mixproof Process valves. These smaller double-seat mixproof valves offer high cleanability, pressure resistance, and adaptability to meet diverse hygienic processing needs. With these new sizes, manufacturers can easily integrate more compact CIP skids, valve matrices and dosing lines into hygienic processing lines while maintaining the safety that mixproof valves deliver.

The latest additions to Alfa Laval’s valve portfolio demonstrate their commitment to meeting the evolving needs of industries where safety, efficiency and reliability are paramount. With the Unique SSV Pressure Relief Valve, Leakage Detection Butterfly Valve, and smaller Unique Mixproof CIP and Process Valves, Alfa Laval continues to provide practical, high-quality valves that enhance operational performance across a broad spectrum of applications.