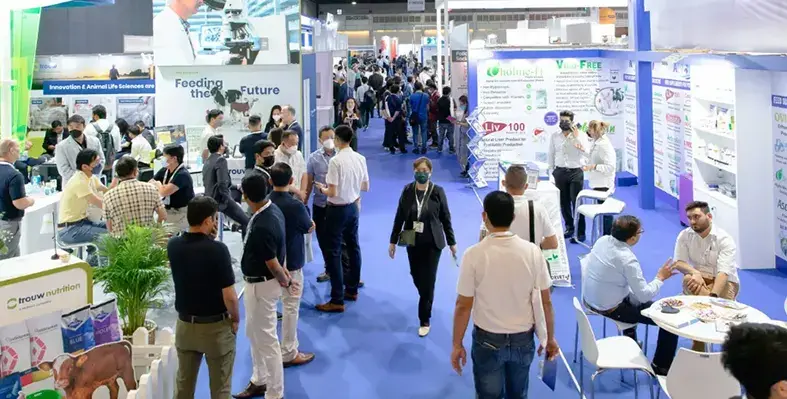

IPPE unites experts from production, processing, manufacturing and allied services. (Image credit: IPPE)

International Production & Processing Expo IPPE stands as the largest annual trade exhibition serving the global meat, poultry, egg and animal food industries.

Hosted every year at the Georgia World Congress Center in Atlanta, Georgia, USA, the event acts as a powerful meeting point for industry professionals seeking insight into the latest developments shaping the protein supply chain.

IPPE unites experts from production, processing, manufacturing and allied services, offering direct access to cutting edge technology, equipment, supplies and solutions. Formed by the collaboration of the International Feed Expo, International Meat Expo and International Poultry Expo, the event draws a truly international audience. Senior decision makers, executives, engineers, researchers and operations leaders attend from across the globe, representing businesses ranging from animal feed producers to poultry processors and egg specialists.

With thousands of exhibitors spread across vast exhibition halls, IPPE provides a comprehensive showcase of innovation. Recent editions have welcomed over 1,300 exhibitors and nearly 31,000 registered attendees, highlighting its growing influence within the sector. Visitors benefit from hands on engagement with suppliers, early exposure to emerging technologies and valuable networking opportunities that support long term business growth.

The expo is carefully organised into dedicated zones covering animal nutrition, animal health, rendering, egg production, live production, food safety, worker safety and meat and poultry processing and packaging. Beyond the exhibition floor, IPPE delivers a strong educational programme, featuring expert led seminars, TECHTalks, product launches, career development initiatives and leadership recognition events.

As a strictly business to business event, attendance is reserved for industry professionals. Revenue generated is reinvested into research, education, public relations, crisis management and regulatory support, ensuring lasting value for the sectors it serves. Overall, IPPE remains a vital global platform for innovation, collaboration and industry advancement.