In The Spotlight

Vietstock has established itself as Vietnam’s leading international exhibition for the feed, livestock, aquaculture and meat industry. (Image credit: VIETSTOCK)

Vietstock Expo & Forum 2026, which is scheduled to take place from 21 to 23 October 2026 at the Saigon Exhibition & Convention Center (SECC) in Ho Chi Minh City, Vietnam, is set to be a major moment for the livestock and aquaculture sectors in Asia.

Over the years, Vietstock has established itself as Vietnam’s leading international exhibition for the feed, livestock, aquaculture and meat industry, and the 2026 edition is expected to reinforce its reputation as a trusted meeting place for professionals from across Southeast Asia and beyond.

Building on the momentum of previous editions, Vietstock 2026 is expected to be one of the largest events in its history. Organisers are projecting around 300 international and local exhibitors and approximately 13,000 trade visitors and professional buyers over the three day show. This scale reflects the growing importance of the region within global food and agriculture systems, as well as the demand for platforms that connect businesses across the entire farm to fork value chain. From feed manufacturers and livestock producers to meat processors and agricultural technology providers, the event offers space for meaningful exchange and collaboration.

A central feature of Vietstock 2026 will be its broad showcase of products, solutions and technologies shaping the future of livestock and related industries. Alongside the exhibition floor, the programme will include industry conferences and technical seminars, as well as specialist forums such as the Antimicrobial Resistance Forum. These sessions are designed to encourage discussion around current challenges and future opportunities, while networking activities such as meet ups and match making programmes will help participants turn ideas into partnerships.

Beyond the main exhibition, 2026 will also see related events delivered under the wider livestock and aquaculture series. According to announcements from Informa Markets, the Aquaculture Vietnam & VietShrimp Asia 2026 event will take place earlier in the year in March at the same SECC venue. Additional livestock and aquaculture exhibitions are also scheduled throughout 2026 in Taiwan and the Philippines, further strengthening regional connections.

Together, these events highlight Vietstock’s growing role in bringing the livestock and aquaculture community together and showcasing the trends, solutions and business opportunities shaping agriculture across Asia in 2026.

VIV Europe 2026 is set to be a landmark event as it celebrates its 25th Edition and reinforces its position as one of the most influential agrifood exhibitions in the world.

Backed by strong international partnerships and near sell out momentum, the event returns to where the VIV Worldwide journey first began, bringing together the global feed to food community at a crucial moment for the industry.

Organised by Royal Dutch Jaarbeurs and VNU Europe, the 2026 edition not only honours VIV Europe’s rich legacy but also signals a forward looking strategy. The organisers have confirmed that from 2028 onwards, VIV Europe will move to a two year cycle, with the next edition scheduled for June 2028. This shift aims to provide greater continuity, consistency and long term value for exhibitors and visitors alike.

Jeroen van Hooff, President and CEO of Royal Dutch Jaarbeurs and VNU, said, “VIV Europe is evolving with the strength, consistency and international depth that the industry has been asking for. Europe needs a reliable and forward-looking agrifood platform to connect strategy, technology and business. VIV Europe 2026 will meet that need and the new two-year rhythm from this year on will provide in the epicenter of Europe, the continuity and momentum that our exhibitors, partners and global community deserve.”

The anniversary edition will welcome around 600 exhibitors showcasing the latest innovations, technologies and machinery across the agrifood value chain. An estimated 20,000 international visitors are expected in Utrecht, one of the world’s leading hubs for agricultural innovation. The programme will be supported by major partners including Rabobank, Wageningen University, the World Poultry Science Association and Common Source, alongside a full week of industry focused activities under the banner of VIV Week.

Poland has been named Country of Honor for 2026, reflecting its status as the leading poultry producer in the European Union and a rapidly growing exporter. Special sessions, delegations and matchmaking activities will spotlight Poland’s dynamic role in animal protein production.

With more than 97 percent of exhibition space already sold, VIV Europe 2026 clearly demonstrates strong market confidence. As Europe’s agrifood sector faces rapid technological change, sustainability demands and global competition, VIV Europe stands out as a vital platform connecting innovation, trade and real business opportunity.

Indonesia has increased its efforts to strengthen domestic milk production by importing 1,383 additional dairy cows from Australia, according to agriculture officials.

The move forms part of a long term plan valued at US$3 bn aimed at dramatically expanding the country’s dairy sector and reducing reliance on imports.

The initiative focuses on encouraging small scale farmers to become key contributors to national milk output. Officials hope the strategy will help Indonesia quadruple its current production capacity while supporting rural livelihoods and improving food security.

Facing budget constraints, the government has taken an unconventional approach by urging private companies to finance livestock purchases. This policy has sparked debate within the business community, particularly as Indonesia continues to balance economic growth with investor confidence.

Agung Suganda, the ministry's director general of livestock and animal health, said,"These cattle are not only an addition to the population. They are a strategic investment to strengthen the foundation of national milk production from smallholder farms."

The dairy expansion programme plays a central role in Indonesia’s free meals scheme, which aims to provide nutrition to 83 million children and expectant mothers. To meet rising demand, the plan calls for the import of one million dairy cows over five years, a significant increase from the current population of around 220,000.

The agriculture ministry explained that the cattle imports involve joint shipments and breeding partnerships between cooperatives and farmers. Since last year, this collaborative model has been designed to ensure that milk produced by smallholders feeds directly into the processing industry, offering stability and predictable supply.

The latest shipment arrived at the port city of Cilacap in Central Java and is now undergoing strict health protocols. "To ensure safety, a 14-day quarantine period will be ... followed by sample collection to detect diseases such as lumpy skin disease and foot-and-mouth disease," said Hendra Wibawa, an animal health official at the ministry.

Private firm Lunar Chemplast imported 1,094 cows, while Mazaraat Lokanatura Indonesia purchased the remaining animals. The ministry also revealed that Indonesia imported 33,955 cows in 2025, with 13,544 designated for dairy production and the rest for beef.

The government believes the programme will reshape Indonesia’s dairy industry and strengthen long term food resilience.

-

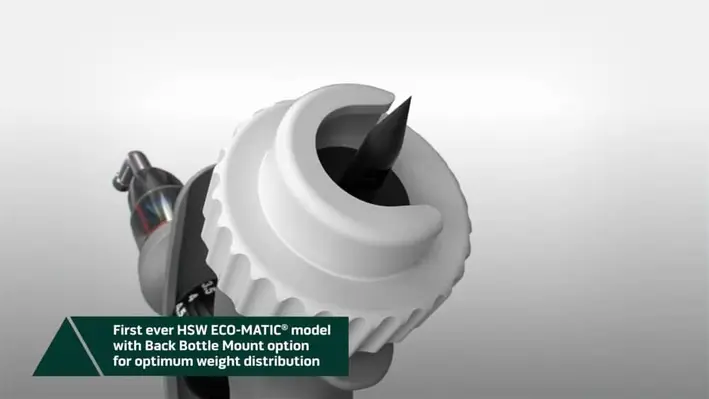

HSW ECO MATIC® 6ml _ 10ml (for injection, oral and pour-on application)

Jakarta, Indonesia

Global agriculture continues to expand, yet the agricultural machinery market is navigating a period of turbulence.

Economic uncertainty, geopolitical tensions and shifting trade policies are reshaping where and how farm equipment is bought and sold. This evolving landscape was outlined during the press conference launching the 47th edition of EIMA International, the world’s leading exhibition for agricultural technologies, set to take place in Bologna from 10 to 14 November.

Mariateresa Maschio, FederUnacoma President, said, “Protectionist policies in some countries, economic sanctions, interference with trade routes, and tariff wars have led to market fragmentation and a sharp slowdown in trade which is weighing on the performance of the agromechanical sector.”

Traditional markets are feeling the strain. The United States recorded a 10 percent fall in tractor sales in 2025, while Germany, France and the United Kingdom also posted double digit declines. In contrast, southern Europe is showing renewed momentum. Italy and Spain both closed the year with strong growth, signalling cautious optimism within the European agricultural machinery industry.

India remains the standout performer. With tractor sales exceeding 1.1 million units, the country continues to dominate the global market. According to Maschio, this growth reflects deeper structural demand rather than a short term spike. “Over the past fifteen years, output in the primary sector has grown significantly,” said Mariateresa Maschio, “but to meet the needs of the world’s population it will have to grow by a further 14% by 2034, especially in India and in those countries of North Africa, Sub-Saharan Africa, and the Middle East that are experiencing the highest demographic growth.”

A new geography of agricultural production is emerging, driven by mechanisation, digital farming solutions and expanding demand in Asia, Africa and Latin America. Chinese manufacturers are rapidly increasing their presence across these regions and even gaining ground in Europe.

“In the coming years we will have a highly segmented agromechanical sector, with low-cost basic technologies alongside highly advanced technologies for complex operations,” added Mariateresa Maschio, underlining the importance of innovation, policy support and international cooperation as the sector looks ahead.

Ceva Animal Health is preparing to mark an important milestone as it commemorates 100 years since Newcastle disease was first identified on the island of Java.

This moment represents the starting point of a century long scientific effort to understand, manage, and control one of the most significant poultry diseases worldwide.

For Ceva, the fight against Newcastle disease is more than a scientific challenge. The company views it as a shared responsibility passed down through generations, with researchers, veterinarians, and poultry professionals all playing a role as guardians in this ongoing battle. Each contribution, past and present, has helped shape the collective knowledge and progress made over the last hundred years.

To honour this legacy, Ceva will host a special event titled ‘100 Years with Newcastle Disease’. The meeting will take place from February 10 to 12, 2026, in Bogor, Indonesia, close to where the disease was first described. The location has been chosen to reflect both the historical significance of Java and the continued global relevance of Newcastle disease today.

According to a joint statement from Mustafa Seçkin Sandikli, Global Poultry Director, and Christophe Cazaban, Poultry Scientific Director, the event will bring together a carefully selected group of leading Newcastle disease researchers alongside senior poultry health and laboratory experts from around the world. The aim is to create an open forum for sharing knowledge, exchanging experiences, and discussing future directions in disease prevention and control.

“Returning to Java, where the story began, we aim to create a meaningful space to reflect on the past, understand today and connect our efforts for the decades ahead,” they said.

The event is expected to highlight both historical achievements and future opportunities in the global fight against Newcastle disease.

INTA and the National University of La Matanza (UNLAM) are working on the optimisation and fine-tuning of a compact, controlled and affordable hydroponic system designed to enable the domestic production of fresh food in small spaces and under variable climatic conditions.

The prototype builds on the experience gained through the Antarctic Hydroponic Production Module (MAPHI).

INTA and UNLAM are jointly developing a module aimed at facilitating vegetable production in reduced spaces, regardless of external climatic variability. The goal is for the final prototype to be economically accessible and simple enough to be used by anyone in a household setting.

The project originates from the know-how developed through MAPHI, a system designed to produce vegetables under the extreme conditions of Antarctica. Drawing on that experience, INTA Santa Cruz, in collaboration with the National University of La Matanza, is now adapting and optimising the technology at a smaller scale, specifically targeted at domestic use.

Jorge Birgi, researcher at the INTA Santa Cruz Experimental Station, said,"we were able to design a production module that condenses the technologies used in the Antarctic system, while adding new features. Given the scale, this is a module that allows a family to produce their own food."

The initial objective was to transform a highly complex system, originally conceived for hostile and isolated environments, into a compact, efficient and economically accessible prototype capable of producing fresh food in limited spaces and under variable climatic conditions.

Martín Díaz, project director overseeing the optimisation phase,said, "this collaboration will provide technical tools that strengthen the prototype and make it possible to reach the goal of developing a product that can be commercialised."

Among its defining features, Díaz explained that "the module is designed to produce vegetables independently of external environmental conditions. It controls all key variables — temperature, light and nutrients to ensure production regardless of location."

During its deployment in Antarctica, the MAPHI project led to the development of a complete technological package. This included compatible substrates, specific seed types, seed treatments and dedicated protocols. A tailored nutrient solution adapted to Antarctic conditions was also developed, along with a monitoring system incorporating sensors and custom-designed electronic boards. These components allowed data to be collected, processed and presented in a way that was easy for operators to interpret.

At this stage, efforts are focused on transforming MAPHI's technologies into a product that can be utilised by society and the productive sector. In other words, the project that proved capable of producing vegetables under extreme Antarctic conditions is now being used as a springboard for the development of commercial products.

In this regard, Birgi noted that "to achieve this objective, the MAPHI team developed a reduced-size prototype that incorporates new functionalities, making it easier to operate in a domestic environment."

Through the joint project, INTA and UNLAM will now contribute a business plan aimed at turning the prototype developed by the Santa Cruz Experimental Station into a commercial product. This phase will include a market study to identify potential user profiles, as well as the development of an intuitive interface allowing the system to be managed via a mobile phone application.

The final outcome will consist of a series of technical documents defining target users, the final price of the production system, the data collection platform to be used, and the materials required for construction.

The initiative is part of the Technological and Social Development Project (PDTS) call, a joint programme promoted by Argentina's National Interuniversity Council (CIN) and the European Union (UNIUEAR).

The latest generation of Braud harvesters demonstrates impressive versatility across a wide range of vineyard structures. (Image credit: New Holland)

New Holland Agriculture continues to set new standards in modern viticulture with its acclaimed Braud grape harvester range - a series celebrated globally for precision, productivity and long-lasting reliability.

Built on decades of specialist expertise, the Braud brand has become synonymous with exceptional grape-harvesting performance, and under the New Holland umbrella it remains a trusted partner for winemakers seeking both efficiency and gentle crop handling.

Each Braud harvester reflects a signature blend of engineering excellence and vineyard-friendly design. The machines are created to treat vines with care while delivering powerful harvesting capability, ensuring that grapes are collected cleanly and with minimal damage. This focus on protecting fruit integrity directly enhances vineyard productivity and supports the production of higher-quality wines.

The latest generation of Braud harvesters demonstrates impressive versatility across a wide range of vineyard structures. With both high-capacity and extra-high-capacity models, including the popular 9000 L and 9000 X series, the range adapts effortlessly to narrow boutique vineyards, expansive commercial estates, and even sloped terrain. Their advanced systems such as the industry-proven Noria basket conveying system, optional destemmer technology, and innovative side-conveyor configurations ensure consistently clean, gentle and efficient fruit handling.

This adaptability makes Braud harvesters an ideal choice for growers looking to streamline operations while maintaining strict quality standards. Backed by a global legacy and trusted by thousands of vineyard operators, these machines are built to deliver season after season, reducing labour needs, improving harvest speed, and preserving overall vine health.

Engineered for durability and operator comfort, the Braud range combines robust construction with intuitive controls, offering ease of use without compromising on precision. The result is a harvester that not only boosts productivity but also supports sustainable agricultural practices, helping vineyards reduce waste and optimise long-term output.

Choosing a Braud grape harvester means investing in a heritage of innovation, reliability and world-leading vineyard technology giving growers confidence in every harvest and reinforcing New Holland’s reputation as a champion of next-generation viticulture solutions.