Earth Rover, a UK based agri-robotics company and Agri-EPI Centre member, has developed the LightWeeder to solve key challenges faced by laser-based weeding systems

The LightWeeder is said to be the world’s first eye-safe, herbicide-free, carbon-neutral, commercially viable weeding system. The LightWeeding technology uses semiconductor LEDs to solve key technical, safety and commercialisation challenges faced by laser-based weeding systems.

The LightWeeder is part of CLAWS (Concentrated Light Autonomous Weeding and Scouting), an agri-robot that can kill weeds using a unique concentrated light method, and can also scout fields to obtain a complete data map of all crops after planting, showing the crops exact location, size, and any early signs of disease.The main features of CLAWS are:

- Weeding – chemical-free and inherently safer than laser weeding. No till and no crop damage and can be used in any conditions without compacting the soil.

- Scouting – In-depth analysis of crops to allow better harvest predictions and increased yields.

The complete system is ultra-lightweight at 300kg, meaning it requires low amounts of energy to run, and is also claimed to be cheaper and more environmentally friendly than many of its competitors. The system currently runs on batteries and in future, solar panels therefore uses no fossil fuels and help farmers meet their net-zero targets.

With increasing types of chemical-resistant weeds, a significant downturn in availability of hand labour plus a shift in society towards more organic options, now more than ever there is a need to change the way we farm. A recent report by Rothamsted Research shows weeds pose an unprecedented threat to our food security and highlights the need to diversify weed control as an urgent priority.

As explained by John Taylor, farm director at Pollybell Organic Farm, “The key element here is that the LightWeeder not only makes chemical-free farming more effective but it also solves the huge issue farmers are facing today in terms of the huge loss in the labour force. Being able to weed fields autonomously means that food production doesn’t just grind to a halt.”

According to Earth Rover, LighWeeder is energy-efficient and no-till and does not cause damage to drip irrigation or crops. It is also not dependent on soil conditions and does not enable weeds to develop resistance.

In The Spotlight

From 20 to 22 May 2026, AGRITECHNICA ASIA and HortEx will gather the global farming community at the Bangkok International Trade & Exhibition Centre. Guided by the theme “Farm. Farmer. Future.”, the event will bring together professionals from across Asia and beyond to explore practical solutions in mechanisation, horticulture and digital agriculture.

Organised by the German Agricultural Society in partnership with Thailand’s Ministry of Agriculture and Cooperatives, the exhibition reflects strong international cooperation. Germany joins as the official partner country, represented by its Federal Ministry of Agriculture, Food and Regional Identity. Eight national pavilions from Austria, China, Germany, India, Japan, the Netherlands, South Korea and Taiwan will highlight global innovation tailored to Asian farming systems.

Around 350 exhibitors and more than 18,000 professional visitors are expected. Major agricultural machinery brands such as CLAAS, AGCO, Mahindra and KUHN will showcase equipment alongside digital pioneers including DJI and Topcon. Visitors will be able to compare machinery, smart farming tools and greenhouse technologies designed to boost efficiency and sustainability.

Katharina Staske, Managing Director, DLG Markets Asia Pacific, said, “AGRITECHNICA ASIA 2026 builds on the success of previous editions while introducing formats that respond to Asia’s dynamic market needs. Our focus is on direct technical exchange so producers can adopt technologies that improve efficiency, reduce pressure, and support more sustainable production.”

The exhibition will be supported by a strong technical programme developed with ministries, universities and international organisations including the Food and Agriculture Organization and the International Rice Research Institute. Discussions will focus on mechanisation, climate resilient systems, sustainable crop production and regional markets.

New features such as the AGRIFUTURE Zone and Startup Day will spotlight innovation and connect emerging enterprises with farmers and investors. The Future Farmers Program will place producers at the centre, encouraging knowledge sharing, professional growth and recognition of leadership in agriculture.

With strong global participation and a clear focus on practical solutions, AGRITECHNICA ASIA and HortEx 2026 aim to shape a resilient and forward looking future for farming in the region.

Aquaculture Philippines 2026 to Spotlight Innovation and Growth in the Fisheries Sector. (Image credit: Livestock Philippines)

Aquaculture Philippines will return from 27 to 29 June 2026 at the World Trade Center in Pasay City, bringing together key players from across the aquaculture, fisheries, and seafood industries.

Held alongside Livestock Philippines, the event serves as a dedicated platform for advancing aquaculture nutrition, health, and production while encouraging meaningful dialogue across the full value chain, from farming and feed development to processing and distribution.

As a nation surrounded by vast waters, the Philippines holds a natural advantage in fisheries and aquaculture. The sector continues to play a vital role in food supply, employment, and rural livelihoods. According to the second quarter report of the Philippine Statistics Authority this year, aquaculture contributes 15.1 percent to the total value of production at 2018 constant prices. This steady contribution underlines the importance of strengthening the industry through innovation, knowledge exchange, and investment.

Aquaculture Philippines 2026 aims to support this progress by showcasing modern technologies, sustainable production methods, aquatic animal health solutions, feed advancements, and efficient processing systems. The exhibition will gather leading local, regional, and international suppliers, offering visitors direct access to products and expertise that can improve productivity and long term viability.

In addition to the exhibition floor, this year’s edition will host a conference session covering a range of current issues in fisheries and aquaculture. Industry experts and practitioners will discuss sector challenges, regulatory developments, market trends, and research findings that influence both domestic and global trade. The sessions are designed to encourage practical learning and open discussion among stakeholders.

By connecting suppliers, producers, processors, policymakers, and researchers under one roof, Aquaculture Philippines 2026 continues its mission to strengthen the country’s aquatic sector and support sustainable growth in the years ahead.

Livestock Philippines 2026 to drive innovation and growth in animal production sector.(Image credit: Livestock Philippines)

Livestock Philippines 2026, the Philippines’ premier international B2B trade exhibition for the livestock, poultry, aquaculture, animal feed, and meat industries, is set to take place at the World Trade Center Metro Manila from 24 to 26 June 2026.

Organised by Informa Markets, the exhibition remains a key meeting point for professionals shaping the future of animal production across the region.

First introduced in 2011, the event has steadily grown into one of Southeast Asia’s most respected industry gatherings. Its expansion reflects the rising demand for modern solutions within the Philippine livestock and poultry sectors. Since 2023, the exhibition has been held annually, responding to strong support from both local and international participants and highlighting the pace at which the sector continues to evolve.

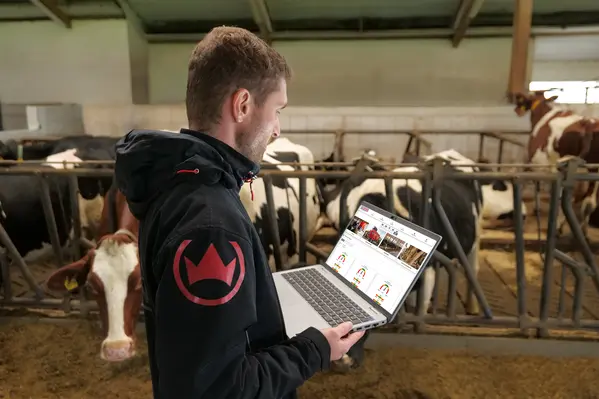

The 2026 edition is expected to welcome hundreds of exhibitors representing more than 30 countries. Companies will present a wide range of products and services, including animal health solutions, feed technologies, breeding advancements, farm management systems, processing equipment, and sustainable production practices. Visitors will have the opportunity to explore practical innovations aimed at improving efficiency, strengthening biosecurity measures, and supporting long term productivity.

Designed exclusively for trade professionals, the exhibition will attract farmers, integrators, veterinarians, feed millers, processors, distributors, researchers, and government representatives. Alongside the exhibition, a series of technical seminars, conferences, and panel discussions will offer valuable insight into current market conditions, policy developments, animal nutrition research, and disease management strategies. These sessions provide a platform for knowledge sharing and open discussion among experts and stakeholders.

Beyond showcasing products and ideas, Livestock Philippines 2026 creates space for meaningful business connections. The event encourages collaboration, new partnerships, and fresh investment opportunities within the ASEAN region and beyond.

As the Philippine agricultural industry continues to strengthen its food security efforts, Livestock Philippines 2026 stands as a clear reflection of the sector’s commitment to innovation, sustainability, and steady growth.

-

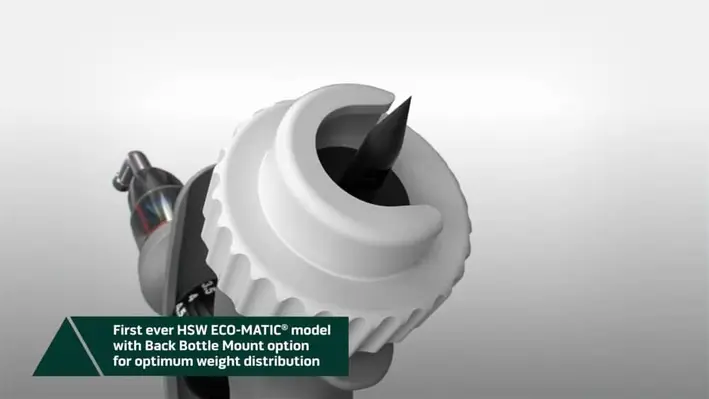

HSW ECO MATIC® 6ml _ 10ml (for injection, oral and pour-on application)

Vietnam’s appetite for imported meat continued to grow in 2025, with total purchases surpassing US$2bn for the first time.

The country imported around 978,300 tonnes of meat and meat products during the year, reflecting strong consumer demand and expanding needs within the food processing sector.

Figures compiled by the Import and Export Department under the Ministry of Industry and Trade, together with the General Department of Customs, show that Vietnam spent more than US$2.004bn on meat imports in 2025. Compared with the previous year, import volumes rose by 11.6 per cent, while the overall value increased by 12.2 per cent. The rise points to a steady shift in consumption patterns, with more households and businesses turning to imported animal protein.

India remained Vietnam’s largest supplier. The country exported 188,700 tonnes of meat to Vietnam, valued at US$681.32mn, accounting for nearly one fifth of total import volume.

Frozen pork was one of the fastest growing segments. Imports reached 183,400 tonnes, worth US$418.54mn. This marked an increase of 18.75 per cent in volume and almost 21 per cent in value compared with 2024.

Vietnam relied heavily on Russia for frozen pork, which supplied 48.44 per cent of total imports in this category. Brazil followed with a 30.91 per cent share, underlining the importance of both countries in meeting Vietnam’s protein needs.

The average import price of frozen pork stood at roughly US$2,273 per tonne. This increase came at a time when domestic live hog prices in early 2026 fluctuated between USD 2.65 and 3.30 per kilogramme, creating additional pressure along the supply chain.

While imports surged, exports remained limited. In 2025, Vietnam exported only 22,300 tonnes of meat, generating US$116.49mn in revenue. Hong Kong remained the largest destination for Vietnamese meat, although shipments to the market declined by more than 21 per cent compared with the previous year.

The figures highlight a widening gap between Vietnam’s import demand and its export capacity, as domestic consumption continues to outpace overseas sales.

Livestock Philippines 2026 to drive innovation and growth in animal production sector.(Image credit: Livestock Philippines)

Livestock Philippines 2026, the Philippines’ premier international B2B trade exhibition for the livestock, poultry, aquaculture, animal feed, and meat industries, is set to take place at the World Trade Center Metro Manila from 24 to 26 June 2026.

Organised by Informa Markets, the exhibition remains a key meeting point for professionals shaping the future of animal production across the region.

First introduced in 2011, the event has steadily grown into one of Southeast Asia’s most respected industry gatherings. Its expansion reflects the rising demand for modern solutions within the Philippine livestock and poultry sectors. Since 2023, the exhibition has been held annually, responding to strong support from both local and international participants and highlighting the pace at which the sector continues to evolve.

The 2026 edition is expected to welcome hundreds of exhibitors representing more than 30 countries. Companies will present a wide range of products and services, including animal health solutions, feed technologies, breeding advancements, farm management systems, processing equipment, and sustainable production practices. Visitors will have the opportunity to explore practical innovations aimed at improving efficiency, strengthening biosecurity measures, and supporting long term productivity.

Designed exclusively for trade professionals, the exhibition will attract farmers, integrators, veterinarians, feed millers, processors, distributors, researchers, and government representatives. Alongside the exhibition, a series of technical seminars, conferences, and panel discussions will offer valuable insight into current market conditions, policy developments, animal nutrition research, and disease management strategies. These sessions provide a platform for knowledge sharing and open discussion among experts and stakeholders.

Beyond showcasing products and ideas, Livestock Philippines 2026 creates space for meaningful business connections. The event encourages collaboration, new partnerships, and fresh investment opportunities within the ASEAN region and beyond.

As the Philippine agricultural industry continues to strengthen its food security efforts, Livestock Philippines 2026 stands as a clear reflection of the sector’s commitment to innovation, sustainability, and steady growth.

Limex has unveiled its latest innovation in industrial washing technology with the introduction of the Modular 8, a highly flexible and configurable washing machine platform designed for crates, seed trays, flower buckets and floats.

The new line marks a significant shift towards modular engineering, allowing customers to build exactly the washing solution they need using standardised components rather than costly custom-built systems.

Unlike traditional crate and tray washers that often require extensive engineering work to meet specific customer requirements, the Modular 8 is built from individual modules that connect seamlessly into a single washing line. These include pre-wash units, one or more main wash modules, rinse sections and blow-off units. This modular approach enables users to tailor the system precisely to their operational layout, hygiene standards and processing capacity.

By installing multiple main wash modules in sequence, the system increases soaking time and washing power, delivering higher throughput without compromising cleaning performance. Each standard module also offers multiple configuration options, such as higher-pressure pumps or advanced filtration technologies. The platform supports both left-hand and right-hand configurations, ensuring maximum flexibility for different production environments.

"With the Modular 8, we make it easier to choose exactly the configuration that matches the customer's capacity, hygiene requirements, and budget," says Joep Janssen, owner of Limex. "Our engineers have designed the machines in such a way that they follow each other seamlessly."

With a tunnel width of 800 millimetres, the Modular 8 is suitable for a broad range of applications, including harvest crates, seed trays, flower buckets and DWC floats. The system has also been designed with maintenance efficiency in mind. Improved accessibility of components simplifies cleaning, inspection and servicing, helping to reduce downtime and improve overall operational efficiency.

The Modular 8 builds on Limex’s reputation for proven, high-quality engineering. Constructed from robust stainless steel, the platform delivers durability, reliability and long service life. Twelve Modular 8 lines are already in operation across multiple countries, demonstrating strong market acceptance.

This launch sets the foundation for future developments, with the Modular 10, Modular 14 and Modular 18 planned to follow. These larger, configurable models will eventually replace Limex’s existing cart washers and big box washers, reinforcing the company’s commitment to modular, future-ready industrial washing solutions.

The Ministry of Agriculture, Food and Rural Affairs (MAFRA) has designated seven provinces Gyeonggi-do, Gangwon-do, Chungcheongnam-do, Gyeongsangbuk-do, Gyeongsangnam-do, Jeollabuk-do, and Jeollanam-do as the first-ever “Green Bio Industry Promotion Zones” in accordance with Article 15 of the Act on the Promotion of the Green Bio Industry.

This milestone marks a significant step in the Republic of Korea’s strategy to strengthen its green bioeconomy and drive sustainable industrial growth.

Introduced for the first time this year, the Green Bio Industry Promotion Zone system is designed to establish a comprehensive, region-led framework for business support. The initiative is built around provincial hubs where green bio companies, universities, research institutes, and essential infrastructure for technology verification and certification are closely integrated. Through this clustered approach, local governments are expected to play a leading role in nurturing innovation, accelerating technology transfer, and supporting market-ready solutions.

The selected zones were evaluated and designated following a rigorous assessment process. Key criteria included industrial growth potential, implementation capacity, policy relevance, and overall feasibility. This ensures that each province is well positioned to contribute effectively to the national green bio strategy while leveraging its own regional strengths and resources.

The green-bio industry itself is regarded as a next-generation growth engine, encompassing six major sectors: microorganisms, natural products, food materials, insects, seeds, and veterinary medical products. With the designation of the Green Bio Industry Development Zones, collaboration networks among provinces are expected to deepen. In parallel, processes for verification, evaluation, certification, and commercialisation of green bio technologies and products are set to accelerate, helping to create a dynamic and competitive innovation ecosystem.

MAFRA plans to support the designated provinces by granting eligibility to participate in government-funded infrastructure development projects, including the Green Bio Venture Campus and advanced biofoundries. In addition, policy incentives will be provided to companies operating within the zones, further encouraging private-sector participation and investment in sustainable bio-based industries.

To ensure accountability and continuous improvement, MAFRA will receive quarterly performance reports from the local governments managing the designated zones. Annual performance evaluations will also be conducted to closely monitor implementation progress. Importantly, the results of these evaluations will be reflected in the formulation of policies for the following year, reinforcing a results-driven and adaptive governance approach.

Through these measures, the ROK aims to position itself at the forefront of green bio innovation, fostering regional development while advancing a resilient, sustainable bioeconomy aligned with global green growth trends.