Earth Rover, a UK based agri-robotics company and Agri-EPI Centre member, has developed the LightWeeder to solve key challenges faced by laser-based weeding systems

The LightWeeder is said to be the world’s first eye-safe, herbicide-free, carbon-neutral, commercially viable weeding system. The LightWeeding technology uses semiconductor LEDs to solve key technical, safety and commercialisation challenges faced by laser-based weeding systems.

The LightWeeder is part of CLAWS (Concentrated Light Autonomous Weeding and Scouting), an agri-robot that can kill weeds using a unique concentrated light method, and can also scout fields to obtain a complete data map of all crops after planting, showing the crops exact location, size, and any early signs of disease.The main features of CLAWS are:

- Weeding – chemical-free and inherently safer than laser weeding. No till and no crop damage and can be used in any conditions without compacting the soil.

- Scouting – In-depth analysis of crops to allow better harvest predictions and increased yields.

The complete system is ultra-lightweight at 300kg, meaning it requires low amounts of energy to run, and is also claimed to be cheaper and more environmentally friendly than many of its competitors. The system currently runs on batteries and in future, solar panels therefore uses no fossil fuels and help farmers meet their net-zero targets.

With increasing types of chemical-resistant weeds, a significant downturn in availability of hand labour plus a shift in society towards more organic options, now more than ever there is a need to change the way we farm. A recent report by Rothamsted Research shows weeds pose an unprecedented threat to our food security and highlights the need to diversify weed control as an urgent priority.

As explained by John Taylor, farm director at Pollybell Organic Farm, “The key element here is that the LightWeeder not only makes chemical-free farming more effective but it also solves the huge issue farmers are facing today in terms of the huge loss in the labour force. Being able to weed fields autonomously means that food production doesn’t just grind to a halt.”

According to Earth Rover, LighWeeder is energy-efficient and no-till and does not cause damage to drip irrigation or crops. It is also not dependent on soil conditions and does not enable weeds to develop resistance.

In The Spotlight

The partnership will unlock new avenues for impact across food systems, carbon resilience, and soil health.

Luminis, a global leader in microbiome intelligence and precision agri-tech solutions, has partnered with Forvis Mazars in India to expand its impact in the aquaculture and soil microbiome sector for agriculture

The partnership will unlock new avenues for impact across food systems, carbon resilience, and soil health. Nalanda Capital Partners, the strategic advisory and capraise arm, facilitated the move.

Rachelle Jensen, CEO of Luminis, said, “By joining forces with Forvis Mazars and Nalanda Capital Partners, we will be able to combine science-backed solutions, powerful industry networks, and catalytic capital to deliver next-gen solutions and rewrite the future of farming.”

The extensive network with Forvis Mazars will enable Luminis to deepen its footprint in India's thriving agri-sector, utilizing its Omni Biome AI platform and deep genomics capabilities to tackle challenges such as soil degradation, yield instability, disease rise, and climate resilience. Luminis is accelerating the deployment of next-gen bioproducts and microbiome-based solutions designed for India's dynamic agri-food systems, leveraging extensive Next Gen Sequencing and AI-driven insights. This expansion will enhance food security and national prosperity, as agriculture and allied activities contribute approximately 16% to India's GDP.

“This partnership marks a strategic step for Forvis Mazars in India as we help farmers to further unlock value in the crop production and aquaculture sectors,” said Ajay Kakra, Associate Partner, Government, Infrastructure & Development sector Advisory Services, Forvis Mazars in India. “By supporting Luminis, we combine innovation with our sectoral expertise to scale microbiome solutions that can transform Indian agriculture and drive real, lasting impact.”

“This partnership represents the exact kind of visionary science and scalable impact Nalanda Capital Partners is proud to back,” added Ayan Desai, co-founder at Nalanda Capital Partners. “Together, we’re planting the seeds for a healthier, more sustainable food system— one microbe at a time.”

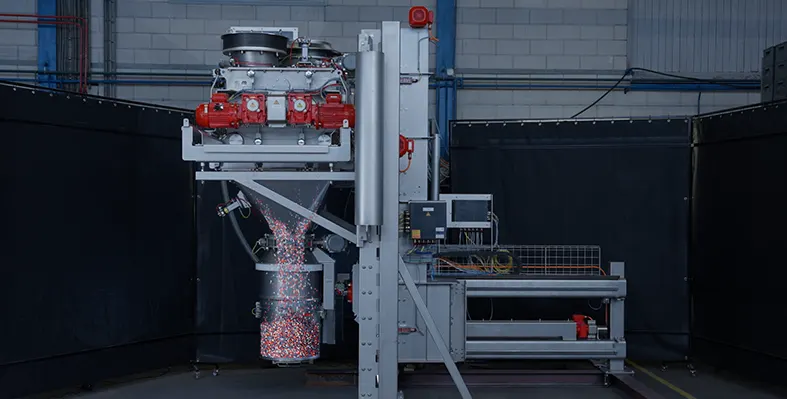

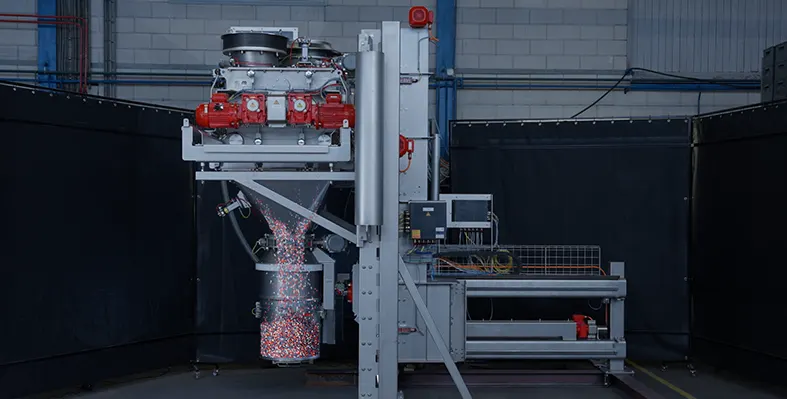

Pegasus Moving Mixer is perfect for industries where hygiene and safety are vital. (Image credit: Dinnissen)

Dinnissen has launched the Pegasus Moving Mixer, a new fully automated mixing system designed for compact production environments

This innovative solution combines safety, hygiene, and precision in one smart, space-efficient unit. The Pegasus Moving Mixer works with movable barrels and mixers, allowing automated handling from start to finish. The barrel containing unmixed product is automatically lifted, rotated, and connected to the Pegasus mixer, where its contents are discharged for mixing. A nitrogen system creates an inert environment before mixing, reducing explosion risks. During the process, liquids and additives are sprayed evenly, ensuring a homogenous mix with no waste.

Once mixing is complete, the mixer moves up and the barrel returns to its position for discharge. The product is returned to the same barrel, without any demixing. This closed-loop process is dust-free, air-free and fully hygienic, making it ideal for food and chemical production.

The system is also highly compact and easy to clean. The unique interaction between the moving mixer and barrel, the Pegasus Moving Mixer makes optimal use of limited floor space. It is fully enclosed, accessible, and designed with safety in mind.

It has fully enclosed system for hygienic operation, even liquid and additive distribution for consistent results, and inert mixing environment with nitrogen injection for explosion safety highlight its advanced safety and hygiene features. With "no manual steps: filling, mixing and discharge are fully automated,” it offers ease of use and consistency. Its compact design ideal for tight production setups makes it suitable for various production environments. Perfect for industries where hygiene and safety are vital, the Pegasus Moving Mixer offers a modern, efficient alternative to traditional systems.

Recently, the Meteorological Services Department of Zimbabwe (MSD), in partnership with Safe4All Africa and the Zimbabwe Farmers’ Union (ZFU), hosted a five-day workshop to address climate change and food insecurity challenges across Africa

Held in the wake of new weather station installations in Mashonaland East, the event brought together meteorologists, journalists, civil society groups, farmers, and other stakeholders for a focused dialogue on climate adaptation and early warning systems.

The workshop was a collaborative platform to share knowledge, promote climate-smart agricultural practices, and scale innovative technologies that enhance community resilience. Safe4All Africa, a non-governmental organisation founded in January 2024 and operating in Zimbabwe, Kenya, and Ghana, showcased several digital tools designed to help smallholder farmers manage climate risks.

Among the tools introduced were the Uliza-WI Chatbox, an AI chatbot providing localised forecasts and real-time farming advice; the Drop App, which tracks rainfall and sends drought alerts; the Climate Impact Atlas, an interactive platform highlighting high-risk climate zones; and a 24/7 Call Center Line, offering voice-based weather updates and expert support for farmers with limited internet access.

With Africa warming nearly twice the global average, and Zimbabwe increasingly vulnerable to droughts and shifting seasonal patterns, such innovations are crucial. Over 60% of Zimbabwe’s population relies on agriculture, making access to timely, localized climate data vital for national food security.

The Zimbabwe Farmers’ Union played a key role in ensuring farmer participation and emphasised the importance of local engagement. “We believe that technology must be rooted in local realities,” said Prince Kuipa, ZFU Operations Director. “By working closely with government agencies and tech innovators, we can ensure that smallholder farmers don’t get left behind in the climate conversation.”

MSD reaffirmed its commitment to expanding localized forecasting and early warning systems. These efforts align with Zimbabwe’s National Adaptation Plan and Vision 2030, the country’s strategy to achieve upper-middle-income status by the end of the decade.

The workshop concluded with a strong call for cross-sector collaboration to build inclusive, tech-enabled climate services that protect people and the planet.

-

HSW ECO MATIC® 6ml _ 10ml (for injection, oral and pour-on application)

A new greenhouse project in Leping, China, brings together multiple innovative agricultural techniques, spearheaded by Growing Smart Technologies

The project, which spans 6.5 hectares, will serve both the city and the province, demonstrating the potential of various technologies and crops on a commercial scale. The greenhouse will feature strawberries grown on hanging gutters, lettuce cultivated using Nutrient Film Technique (NFT) and a nursery for young plants.

Roy Peleg of Growing Smart Technologies, said, "Other than being technologically possible, we also want to make sure that it will be feasible economically." He highlights China's growing horticultural industry, particularly in its western regions, which have seen rapid expansion in recent years. "The economic growth has been rapid, and the fascination for safe and quality-grown food is high," Peleg adds, reflecting on his experiences in China since 2003.

The greenhouse is divided into four distinct zones, catering to the high demand for strawberries in China and other crops such as tomatoes, cucumbers, and melons. These will be grown under an F-Clean roof, which offers advantages over traditional glasshouses, particularly in the region's harsh winters and humid summers. Peleg explains, "F-clean coverage provides more advantages than a glasshouse, especially if you have to deal with natural ventilation." The project also includes a hydroponic lettuce zone and a nursery to support the local agricultural community.

A significant feature of the project is its alignment with Global GAP guidelines, even though these standards are not yet required in China. Peleg states, "We want this project to be prepared for the future and to teach the staff at the site how to work on common standards in growing."

After completing the greenhouse, Growing Smart Technologies will provide ongoing support for two years, including maintenance and crop management training. The facility will also include a visitor area to showcase the project's techniques without direct access to the greenhouse.

Roy Peleg is confident that this project will help drive the development of China's high-tech horticulture sector forward. "We demonstrate the basic monitoring systems and the various soilless growing systems, including the strawberry gutters," he explains. "Then there's the nursery with the overhead irrigation and gutter booms." With further research on crop varieties and climate strategies, the team aims to prepare the project for long-term success.

Despite China's rapid pace of development, Peleg concludes, "In China, construction projects can be realized rapidly. That's different from horticulture." The goal is to prove that high-tech horticulture can thrive in China, technically and economically.

The partnership will unlock new avenues for impact across food systems, carbon resilience, and soil health.

Luminis, a global leader in microbiome intelligence and precision agri-tech solutions, has partnered with Forvis Mazars in India to expand its impact in the aquaculture and soil microbiome sector for agriculture

The partnership will unlock new avenues for impact across food systems, carbon resilience, and soil health. Nalanda Capital Partners, the strategic advisory and capraise arm, facilitated the move.

Rachelle Jensen, CEO of Luminis, said, “By joining forces with Forvis Mazars and Nalanda Capital Partners, we will be able to combine science-backed solutions, powerful industry networks, and catalytic capital to deliver next-gen solutions and rewrite the future of farming.”

The extensive network with Forvis Mazars will enable Luminis to deepen its footprint in India's thriving agri-sector, utilizing its Omni Biome AI platform and deep genomics capabilities to tackle challenges such as soil degradation, yield instability, disease rise, and climate resilience. Luminis is accelerating the deployment of next-gen bioproducts and microbiome-based solutions designed for India's dynamic agri-food systems, leveraging extensive Next Gen Sequencing and AI-driven insights. This expansion will enhance food security and national prosperity, as agriculture and allied activities contribute approximately 16% to India's GDP.

“This partnership marks a strategic step for Forvis Mazars in India as we help farmers to further unlock value in the crop production and aquaculture sectors,” said Ajay Kakra, Associate Partner, Government, Infrastructure & Development sector Advisory Services, Forvis Mazars in India. “By supporting Luminis, we combine innovation with our sectoral expertise to scale microbiome solutions that can transform Indian agriculture and drive real, lasting impact.”

“This partnership represents the exact kind of visionary science and scalable impact Nalanda Capital Partners is proud to back,” added Ayan Desai, co-founder at Nalanda Capital Partners. “Together, we’re planting the seeds for a healthier, more sustainable food system— one microbe at a time.”

Pegasus Moving Mixer is perfect for industries where hygiene and safety are vital. (Image credit: Dinnissen)

Dinnissen has launched the Pegasus Moving Mixer, a new fully automated mixing system designed for compact production environments

This innovative solution combines safety, hygiene, and precision in one smart, space-efficient unit. The Pegasus Moving Mixer works with movable barrels and mixers, allowing automated handling from start to finish. The barrel containing unmixed product is automatically lifted, rotated, and connected to the Pegasus mixer, where its contents are discharged for mixing. A nitrogen system creates an inert environment before mixing, reducing explosion risks. During the process, liquids and additives are sprayed evenly, ensuring a homogenous mix with no waste.

Once mixing is complete, the mixer moves up and the barrel returns to its position for discharge. The product is returned to the same barrel, without any demixing. This closed-loop process is dust-free, air-free and fully hygienic, making it ideal for food and chemical production.

The system is also highly compact and easy to clean. The unique interaction between the moving mixer and barrel, the Pegasus Moving Mixer makes optimal use of limited floor space. It is fully enclosed, accessible, and designed with safety in mind.

It has fully enclosed system for hygienic operation, even liquid and additive distribution for consistent results, and inert mixing environment with nitrogen injection for explosion safety highlight its advanced safety and hygiene features. With "no manual steps: filling, mixing and discharge are fully automated,” it offers ease of use and consistency. Its compact design ideal for tight production setups makes it suitable for various production environments. Perfect for industries where hygiene and safety are vital, the Pegasus Moving Mixer offers a modern, efficient alternative to traditional systems.

Entocycle, a UK-based developer of insect farming technology that transforms food waste into sustainable protein for animal feed, has collaborated with Siemens to launch the country’s first digitalised insect farm showroom

The facility is uniquely located beneath four Victorian railway arches in central London.

Focused on creating a sustainable protein alternative, Entocycle chose the high-profile London Bridge area to boost visibility, attract top talent, and engage potential investors in its innovative approach to circular food systems.

Before construction began, Entocycle used Siemens’ digital twin technology to create a virtual model of the site. This simulation helped maximise the use of the complex arch-shaped space and minimise construction errors, saving time and costs.

The site has since undergone a full digital transformation and now runs on Siemens AI and automation systems. Advanced technologies integrated into the facility include robotic arms, machine vision systems that monitor 3,000 larvae per second with up to 100% accuracy, and climate-controlled chambers. These upgrades have significantly enhanced production by reducing larvae growth time and improving survival rates by 30%.

Now in operation for a year, the facility has demonstrated that insect farming can address two major environmental challenges: cutting the UK’s annual 10.7 million tonnes of food waste (of which 30% is lost through supply chain inefficiencies) and reducing reliance on 3.3 million tonnes of imported soy used for animal feed.

With proof of concept established, Entocycle plans to expand its model to industrial scale, aiming to support farms, agri-businesses, and waste management companies in cutting emissions and rethinking protein supply chains.

Matt Simonds, managing director at Entocycle, said: “We’ve spent a decade developing this concept, which has grown from equipment pieced together from hardware retailers to the bespoke and highly advanced factory we’re running today. The London Bridge centre proves our concept, which leverages the black soldier fly as nature’s recycler, that can be scaled around the world to help tackle the dual issue of food waste and sustainability issues in animal feed supply.

“Insect farming is an exciting emerging industry, and our vision is to be the go-to provider of technology to customers alongside our partner Siemens. In 10 years’ time, we expect Entocycle-designed farms to be processing millions of tonnes of food waste around the world, saving millions of tonnes of carbon emissions with it. Partnering with Siemens to deliver our solution internationally provides us with the trust and scalability we need to deliver on our global ambitions.”

Keith Thornhill, head of food and beverage for UK & Ireland at Siemens said: “Entocycle has created the blueprint for high-tech insect farming. It’s successfully applied modern manufacturing technology to its highly niche subject of rearing black soldier flies. And the outcomes are clear to see in increased insect survival rates and slashing the time staff would spend counting insects.

“It’s a fantastic concept ready to be delivered to customers around the world, regardless of site size and location. We’re proud to support it as a great example of technology with a purpose in addressing crucial sustainability challenges.”