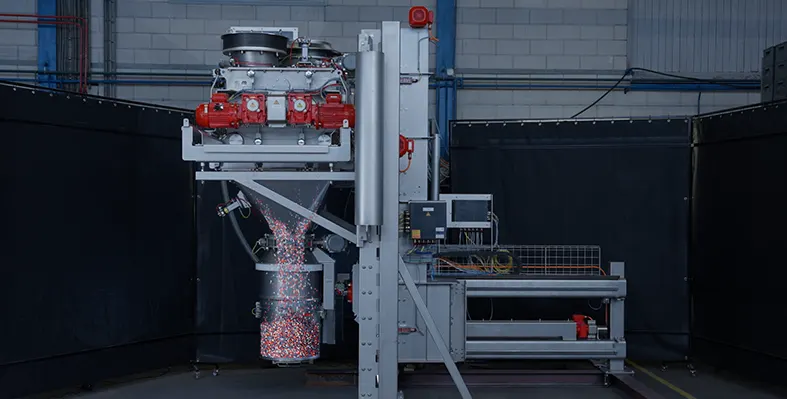

Pegasus Moving Mixer is perfect for industries where hygiene and safety are vital. (Image credit: Dinnissen)

Dinnissen has launched the Pegasus Moving Mixer, a new fully automated mixing system designed for compact production environments

This innovative solution combines safety, hygiene, and precision in one smart, space-efficient unit. The Pegasus Moving Mixer works with movable barrels and mixers, allowing automated handling from start to finish. The barrel containing unmixed product is automatically lifted, rotated, and connected to the Pegasus mixer, where its contents are discharged for mixing. A nitrogen system creates an inert environment before mixing, reducing explosion risks. During the process, liquids and additives are sprayed evenly, ensuring a homogenous mix with no waste.

Once mixing is complete, the mixer moves up and the barrel returns to its position for discharge. The product is returned to the same barrel, without any demixing. This closed-loop process is dust-free, air-free and fully hygienic, making it ideal for food and chemical production.

The system is also highly compact and easy to clean. The unique interaction between the moving mixer and barrel, the Pegasus Moving Mixer makes optimal use of limited floor space. It is fully enclosed, accessible, and designed with safety in mind.

It has fully enclosed system for hygienic operation, even liquid and additive distribution for consistent results, and inert mixing environment with nitrogen injection for explosion safety highlight its advanced safety and hygiene features. With "no manual steps: filling, mixing and discharge are fully automated,” it offers ease of use and consistency. Its compact design ideal for tight production setups makes it suitable for various production environments. Perfect for industries where hygiene and safety are vital, the Pegasus Moving Mixer offers a modern, efficient alternative to traditional systems.