Due Diligence Horticulture (DDH) has unveiled Quantum Clear, a new range of cold plasma devices designed to combat the persistent problem of airborne pathogens in controlled environment agriculture.

Whether cultivating cannabis, ornamentals, or fresh produce, growers constantly contend with mould, bacteria and other threats particularly in humid rooms or tightly packed storage spaces. DDH’s latest innovation aims to change that balance.

Over the last two years, the company has worked closely with an industrial plasma specialist to adapt cold plasma systems specifically for horticultural and agricultural settings. The result is a suite of Quantum Clear (QC) units engineered for grow rooms, HVAC systems, cold storage, and shipping containers.

Travis Higginbotham of DDH explains that the technology already had a legacy in other industries, but needed refinement for plant environments. "We worked through two full years of design and testing so the equipment could function inside grow facilities, centralized HVAC systems, shipping trailers, and cold rooms," he says. That development period included USDA fruit trials, extensive third-party air-quality analysis on 50 pathogens, and pilot projects with large cannabis and ornamental producers.

A key advantage is that this plasma field does not generate ozone an issue that has hindered some older plasma approaches. The QC units carry both UL and CARB certifications, confirming that they are safe for plants and for staff working within indoor facilities.

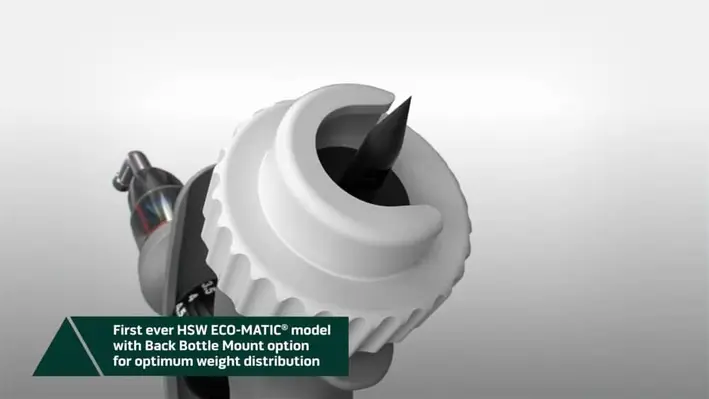

The system is straightforward by design. Air is drawn through the device, passes through an energised plasma zone, and emerges treated. In that field, reactive oxygen and nitrogen species—such as hydroxyl radicals and hydrogen peroxide form naturally and break down airborne pathogens and volatile organic compounds. As Travis puts it, "The idea is to create a field in the environment that breaks down cell walls and alters the structure of certain compounds."

Fruit storage and shipping have been an early proving ground. "The combination of darkness, low temperatures, humidity, and tightly packed produce creates ideal conditions for mold," he notes. USDA trials on bananas, tomatoes, apples, and strawberries found that cold-plasma-treated shipments retained firmness and showed virtually no visible mould.

Importantly, DDH focused on ensuring safety for both crops and growers. Even at double or triple application intensity, "we did not see negative effects," Travis says. Some trials even hinted at neutral or improved yields. For cannabis operators, the technology offers a potential solution to airborne contaminants linked to compliance failures, including aspergillus. A recent grower trial showed a 90% drop in aspergillus counts within just four days.

QC devices are standalone, easy to install, and available in multiple sizes and voltages. There are no subscription costs, and financing options are provided. Across all trials, DDH reports an average pathogen reduction of 87.2% within a week, rising to 95%+ during continuous month-long operation. As Travis explains, "The focus is getting the technology in growers hands through our trial program and building confidence that QC is the solution they have been waiting for."