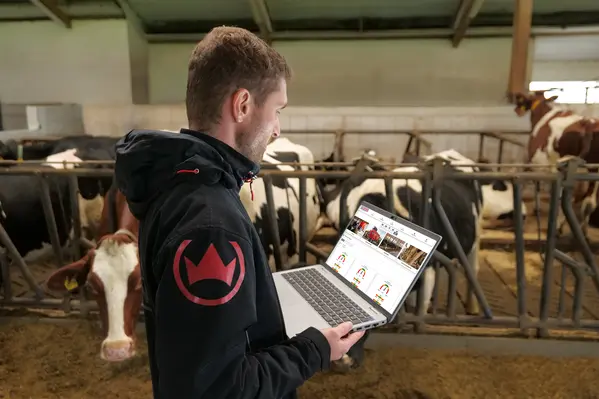

Agrico Web Control is redefining how farmers manage irrigation, offering a fully remote and intelligent system that can be accessed from any internet-connected device

This innovative solution allows users to oversee and operate all aspects of their irrigation infrastructure from centre pivots to pumps through a single, integrated platform.

Designed to simplify the complexities of large-scale farming operations, Web Control gives farmers real-time visibility and control over key elements such as dam levels, valves, irrigation blocks, and pump stations. Whether you're in the field or across the globe, you can monitor and manage your irrigation systems with just a smartphone, tablet, or computer.

One of the standout features is Agrico Advanced RAIN, which automates centre pivot irrigation based on water pressure. It helps detect and alert users to any system irregularities, enabling swift response and reducing downtime. Key capabilities include detailed sector configuration, alert triggers, historical performance tracking, and instant SMS or missed call notifications when status changes occur.

Complementing this is the Agrico Pump Controller, which ensures efficient and intelligent pump management. It supports a variety of starter systems including direct-on-line, star-delta, soft starters, and variable speed drives (VSDs). This tool automates operations, optimises energy use, and supports the integration of additional sensors for flow, vibration, and level monitoring.

A notable enhancement to the platform is its GPS-based end-pressure control. Especially useful for farms with uneven terrain, this feature allows the system to track the final tower in a centre pivot and monitor pressure levels at that point. When possible, the pump’s speed is automatically reduced, conserving energy without compromising performance.

Salinla Seehaphan, Corporate Affairs Director, Nestlé (Thai) Ltd., said,“Marketing cannot be done the same way year after year and expect different results it’s madness.”

With energy-saving features, intelligent automation, and comprehensive system integration, Agrico Web Control offers a cutting-edge solution for farmers seeking efficiency, sustainability, and precision in irrigation.