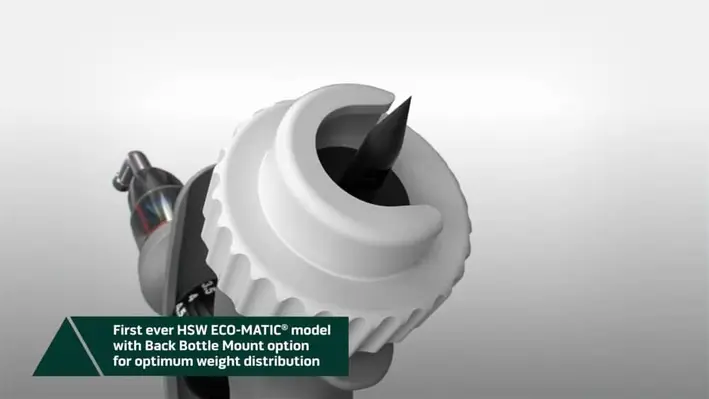

One effective method being adopted by many modern farms is the use of Pure Hypochlorous Acid (PHA)(Image credit: Hydroponic Systems)

Irrigation systems often face wear and tear over time, but few growers realise that the water itself can be one of the main culprits behind this deterioration

According to the team at Hydroponic System, “Growers rarely consider water as an agent that accelerates the deterioration of their infrastructure. However, irrigation water can carry microorganisms, sediments, and organic compounds that form biofilms inside gutters, drip systems, filters, and pipes.” These biofilms not only cause blockages and disrupt irrigation uniformity, but also accelerate biological corrosion, which shortens the life of these systems. That’s why installing a dedicated water disinfection system is increasingly being seen not just as a hygiene solution but as a long-term investment in infrastructure.

One effective method being adopted by many modern farms is the use of Pure Hypochlorous Acid (PHA). This disinfectant is broad-spectrum and cost-effective to generate on-site. It works efficiently against bacteria, fungi, algae, and especially biofilms that form in pipes and other parts of irrigation networks. Unlike harsher chemicals, PHA doesn’t corrode plastic or metal components when used correctly. It's safe for continuous use in recirculating systems and is even suitable for organic farming. “Installing a water disinfection system for agricultural use is not only a sanitary measure but also an investment in the durability of channels and pipes.”

By preventing biofilm buildup, PHA keeps internal surfaces clean, reduces friction and corrosion, and helps maintain steady water flow. This is essential for avoiding water stress and achieving uniform irrigation—especially important in high-value crops like strawberries, cherry tomatoes, or peppers. It also lowers the need for harsh mechanical cleaning, aggressive flushing, or early pipe replacements, helping farmers cut down on maintenance time and costs.

In dry regions where pad-and-fan cooling systems are common, PHA also extends the life of water-contact parts. Compared to other treatments, it stands out for its balance between effectiveness and material safety. While chlorine and hypochlorite are powerful, they can damage seals and plastics. UV systems help in pretreatment but don't eliminate existing biofilm. Peroxides may aid oxygenation but offer limited long-term protection. PHA, by contrast, works continuously, supports beneficial microbes, and is well-suited for systems with recirculation, external piping, or open gutters.

PHA systems are especially valuable in greenhouses that reuse drainage water, where pathogen and biofilm build-up is a frequent issue. They’re also ideal for farms dealing with clogged drippers or routine pipe replacements. When correctly sized, a PHA unit reduces chemical and labour demands and enables remote monitoring, often paying for itself within just a few crop cycles. Ultimately, treating irrigation water with PHA is both a preventative and protective measure that enhances system reliability and longevity, contributing to healthier crops and more profitable operations.