This collaboration integrates their platforms, offering users the ability to monitor and track their assets. (Image credit: Razor Tracking)

CLAAS and Razor Tracking have formed a strategic partnership to enhance farm equipment management and support vehicle tracking

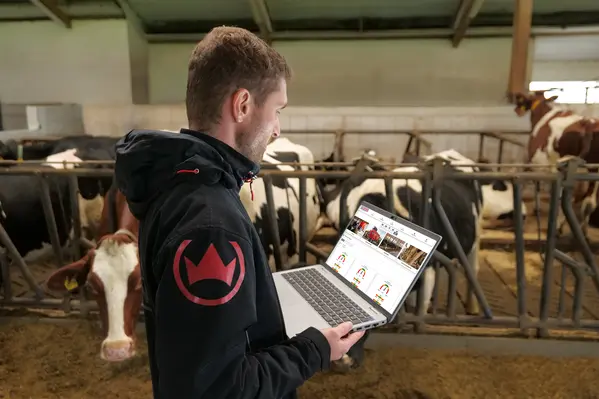

This collaboration integrates their platforms, offering users the ability to monitor and track their assets across both Razor Tracking and CLAAS Connect platforms.

The integration allows farmers to view their equipment, service vehicles, and non-powered assets in real-time. Razor Tracking devices not only provide GPS location but also offer valuable insights such as vehicle VIN, fuel levels, operating hours, engine status, location history, heading, weather overlays, and speed. This comprehensive data ensures better visibility, helping farmers ensure crew members are working in the correct fields and making deliveries to the right locations, ultimately improving operational transparency.

Eric Raby, Senior Vice President of CLAAS Americas, highlighted the importance of smart logistics in modern agriculture. “Knowledge is power. Nowhere is that more evident than on a modern farm where smart logistics and equipment tracking are crucial for saving both time and money,” he said. This partnership seeks to streamline fleet management, extending its capabilities beyond CLAAS equipment, offering a robust solution to optimise farming operations.

Eric Mauch, Managing Partner of Razor Tracking, also emphasised the value of the partnership. “We’re proud to be a GPS Telematics integration partner with CLAAS in North America,” he stated. “This partnership combines our advanced GPS tracking technology with our deep roots in agriculture, allowing customers to seamlessly monitor and manage all of their equipment across multiple farm locations from one powerful platform.”

By merging the strengths of both companies, this integration aims to provide farmers with a more efficient and transparent way to manage their fleets, improving decision-making and overall farm productivity. With the combined power of Razor Tracking's telematics technology and CLAAS' expertise, the partnership offers a holistic solution for equipment tracking and fleet management in the agricultural sector.