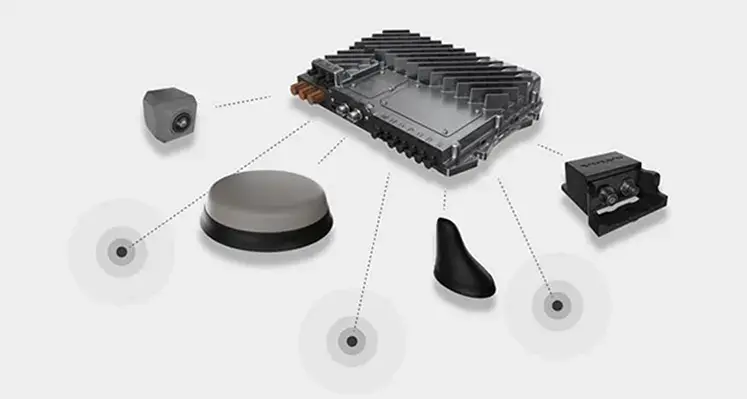

The High-Performance ECU to which you can connect sensors and subsystems to meet the features enabled.(Image credit: Volvo Penta)

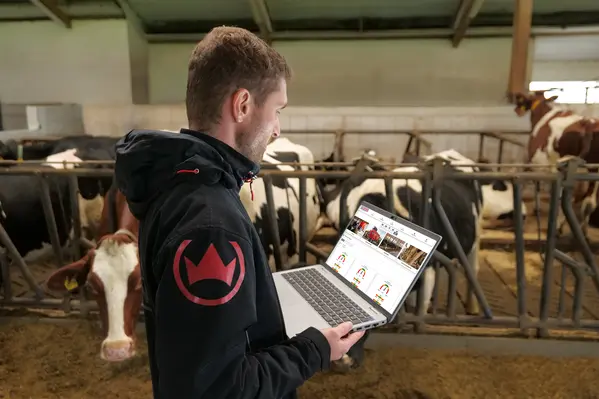

Volvo Penta showcased Volvo Penta Co-Pilot, its smart off-highway productivity solutions, for the first time at Agritechnica 2025, highlighting its commitment to innovation, connectivity, and enhanced machine performance.

Designed to help businesses improve efficiency and competitiveness, the advanced vehicle control system opened new possibilities for Original Equipment Manufacturers (OEMs) and end customers across productivity optimisation, digital connectivity, and intelligent vehicle management.

At Agritechnica 2025, Volvo Penta placed the spotlight on Volvo Penta Co-Pilot as a robust, scalable solution for the off-highway sector. Built on proven Volvo Group technologies, the platform provided OEMs and operators with a unified interface to access critical data, insights, and tools. Its flexible architecture allowed multiple features and user interfaces to coexist, ensuring seamless scalability and future readiness as operational demands evolved.

Volvo Penta Co-Pilot was engineered to support fleet owners and machine operators in managing projects more effectively. The system integrated a fully connected machine HMI, advanced machine controls, and a perception camera to enhance on-site safety. Additional capabilities included tyre pressure monitoring, service and maintenance information, and intelligent operator support tools. The platform also supported operator coaching through smart features such as high-precision positioning, load assist on-board weighing (OBW), and vehicle stability control, helping to maximise uptime and operational accuracy.

“In line with our collaborative, partnership approach at Volvo Penta, we worked with customers to tailor the solution to meet their specific needs,” explained Emil Andersson, product planning Industrial, Volvo Penta. “This means they could customize the platform, add to it, and adapt it as their requirements changed, making it a future-proof solution.”

Alongside Volvo Penta Co-Pilot, the company reinforced its reputation as a trusted partner in power solutions for the agricultural and off-highway sectors. Under the theme ‘Made To Move You – Moving Further. Together’, visitors explored the D16 combustion engine, exhaust aftertreatment systems (EATS), and a remanufactured engine, all reflecting Volvo Penta’s focus on performance, reliability, and sustainability.