In The Spotlight

China boosts crop breeding & tightens seed variety management

China is stepping up its efforts in crop breeding and seed variety regulation in order to improve agricultural resilience, productivity, and innovation

On 29 August, the Seed Industry Management Department of the Ministry of Agriculture and Rural Affairs (MARA), together with its Science & Technology Development Centre and related bodies, held a national conference in Chongqing to address these issues. New crop varieties have already been introduced, including drought‑ and disease‑resistant wheat, machine‑harvestable corn, and high‑oil, high‑protein soybeans.

However, MARA identified problems such as imitative breeding and variety homogenisation-where many seed varieties are too similar and offer little distinct benefit. To tackle this, MARA called for “targeted and robust measures” to eliminate imitation, encourage genuine innovation, and remove seed varieties that lack market value. A variety management action plan is in place, aiming to improve germplasm utilisation, speed up breeding innovation, tighten trial and approval procedures, phase out underperforming varieties, and strengthen protection of plant variety rights. The plan aims to reduce “inflation” in approved varieties and seriously address variety homogenisation within three years.

At the same meeting, China unveiled the National Crop Germplasm Resources Management and Sharing Platform, a digital tool that gives access to over 300,000 germplasm resources across 26 crops like rice, maize, soybean, wheat and vegetables. The platform provides information about access paths, supplying institutions, and sharing status, helping breeders and researchers find and use these materials more efficiently. MARA said it will work to improve the platform's search functions and accelerate exchange of high‑quality resources.

Implementation is expected to involve stronger coordination between national and provincial agencies, clear deadlines, and concrete measures. MARA emphasises that the action plan must be carried out in a “checklist‑based, closed‑loop manner” to ensure all tasks are completed and deliver tangible results.

Together, these efforts represent China’s resolve to modernize its seed sector, support original innovation, and ensure variety offerings are meaningful and useful. With stricter regulation, enhanced breeding innovation and better use of germplasm, China hopes to dramatically improve how new seed varieties are developed, approved, and supplied to farmers.

UC7 Plus: the next generation of boom control technology

Topcon Agriculture has launched the UC7 Plus, the next generation of its boom height control technology for agricultural spraying applications

Built on the solid foundation of Topcon’s Norac boom height control systems, the UC7 Plus helps farmers and crop service providers lower inputs, improve crop performance, and reduce equipment maintenance costs with enhanced spray control and height management capabilities.

The new technology is compatible with most self-propelled and pull-type sprayers, and features advanced sensor technology designed to boost performance and reliability. The UC7 Plus includes the dynamic chassis sensor (DCS-1) to improve the stability and responsiveness of the boom control system. Additionally, the latest MS-1 sensors with MAX Sense ultrasonic technology enhance performance even in challenging terrains. These sensors are built to endure tough field conditions with features such as corrosion-resistant GF nylon housing, a protective transducer screen, and multi-axis vents.

Nick Townsend, Vice President of Topcon Agriculture, highlighted the benefits of the technology. “The combination of proven legacy solutions with the latest in precision technology serves up an extreme opportunity for lower operating and input costs, and lower equipment repair costs,” he said. “Spraying system advances increasingly provide farmers and service providers with an opportunity to achieve a greater return on investment on their equipment, either through upgrades or new investments. The UC7 Plus directly drives those savings.”

The UC7 Plus technology also supports sustainability efforts by ensuring that only the necessary amount of spray is applied where needed, helping farmers achieve optimal crop performance while meeting compliance standards and saving on costs. Furthermore, the technology significantly reduces operator stress and fatigue by automating boom height adjustments to match land contours, removing the need for constant monitoring of field terrain.

With improved spraying performance by up to 30%, according to Topcon’s testing data, the UC7 Plus provides a practical and efficient solution for farmers, offering incremental upgrades to existing systems and further cost-saving potential.

This collaboration integrates their platforms, offering users the ability to monitor and track their assets. (Image credit: Razor Tracking)

Smarter agriculture telematics: CLAAS and Razor Tracking integration

CLAAS and Razor Tracking have formed a strategic partnership to enhance farm equipment management and support vehicle tracking

This collaboration integrates their platforms, offering users the ability to monitor and track their assets across both Razor Tracking and CLAAS Connect platforms.

The integration allows farmers to view their equipment, service vehicles, and non-powered assets in real-time. Razor Tracking devices not only provide GPS location but also offer valuable insights such as vehicle VIN, fuel levels, operating hours, engine status, location history, heading, weather overlays, and speed. This comprehensive data ensures better visibility, helping farmers ensure crew members are working in the correct fields and making deliveries to the right locations, ultimately improving operational transparency.

Eric Raby, Senior Vice President of CLAAS Americas, highlighted the importance of smart logistics in modern agriculture. “Knowledge is power. Nowhere is that more evident than on a modern farm where smart logistics and equipment tracking are crucial for saving both time and money,” he said. This partnership seeks to streamline fleet management, extending its capabilities beyond CLAAS equipment, offering a robust solution to optimise farming operations.

Eric Mauch, Managing Partner of Razor Tracking, also emphasised the value of the partnership. “We’re proud to be a GPS Telematics integration partner with CLAAS in North America,” he stated. “This partnership combines our advanced GPS tracking technology with our deep roots in agriculture, allowing customers to seamlessly monitor and manage all of their equipment across multiple farm locations from one powerful platform.”

By merging the strengths of both companies, this integration aims to provide farmers with a more efficient and transparent way to manage their fleets, improving decision-making and overall farm productivity. With the combined power of Razor Tracking's telematics technology and CLAAS' expertise, the partnership offers a holistic solution for equipment tracking and fleet management in the agricultural sector.

Vietnam turns industrial waste into fertiliser

Vietnam is set to welcome a pioneering sustainable agriculture initiative, as Japanese biotech firm CHITOSE and Vietnamese environmental solutions company TA Vital join forces to transform industrial sludge into agricultural compost

This collaborative project marks a significant step toward Vietnam’s net-zero emissions goal by 2050, aligning with the nation’s broader environmental and circular economy ambitions.

The facility, under construction in the Prodezi Industrial Park—one of Vietnam’s first recognised eco-industrial zones—is expected to begin trial production by the end of 2025. During the initial phase, the compost produced will be used for landscaping purposes within the park itself, due to variability in sludge content sourced from multiple factories.

At the heart of this initiative is CHITOSE’s advanced composting technology, which employs an industrial-scale barrel system combined with a custom microbial blend. This enables the effective breakdown and detoxification of sludge materials, converting up to 80% into usable compost. Integrated AI monitoring tools track fermentation conditions in real time, optimising temperature, moisture, and microbial activity to ensure consistent quality.

A key innovation lies in the ability to tailor the nutrient content of the compost to meet the specific needs of crops—such as dragon fruit—enhancing yield and soil health. Although initial applications will focus on non-food plants, the long-term goal is to expand into food crop fertilisation by working directly with factories producing more consistent, organic waste streams.

Another future ambition is to shift from Japanese-sourced equipment to local production, helping reduce costs and expand deployment across Vietnam and potentially Southeast Asia.

By transforming waste into high-value agricultural input, this project stands as a practical model of the circular economy in action. It not only supports industrial sustainability but also holds promise for reducing chemical fertiliser use and improving soil resilience—two critical needs for climate-smart agriculture in the region.

As Vietnam continues to advance its green agenda, this sludge-upcycling venture represents a meaningful step toward a more regenerative and resource-efficient future.

The future of marine resources: Philippines and BBNJ

The Philippines is intensifying its efforts to ratify a landmark international treaty aimed at protecting marine biodiversity in areas beyond national jurisdiction (BBNJ), reinforcing its commitment to ocean conservation and sustainable marine resource management

The Department of Agriculture (DA) has pledged full support to the Department of Foreign Affairs (DFA) in promoting the Senate’s concurrence to the Agreement on the Conservation and Sustainable Use of Marine Biological Diversity of Areas Beyond National Jurisdiction (BBNJ). Signed under the framework of the United Nations Convention on the Law of the Sea (UNCLOS), the BBNJ treaty addresses the conservation and equitable use of marine resources in high seas and other regions beyond exclusive national control.

Although Ferdinand Marcos Jr., President ratified the agreement in 2024-a year after its global adoption - the treaty still requires Senate concurrence before the Philippines can officially participate.

Francisco P. Tiu Laurel Jr., Agriculture Secretary emphasised the agreement's relevance for the Philippines, said, “The BBNJ Agreement is crucial for conserving and sustainably managing marine biodiversity in areas beyond the Philippines’ jurisdiction, allowing the country to safeguard its rich marine ecosystems while ensuring fair access to and equitable sharing of benefits from marine genetic resources.”

As a nation composed of over 7,000 islands and located near areas beyond national jurisdiction (ABNJ), the Philippines has a strong stake in the treaty’s success. It was an early signatory and active participant in the negotiation process, aligning with global conservation goals and the principles of the 2016 South China Sea Arbitration Award.

Undersecretary for Fisheries Drusila Esther Bayate stressed the strategic timing of the ratification: once approved by the Senate, the Philippines will be eligible to participate in the first Conference of Parties (COP1). This milestone event is expected to take place shortly after 60 countries submit their ratification instruments to the United Nations. As of late August, 55 nations have completed the process, with momentum building towards reaching the required threshold during the UN General Assembly from September 23–26.

The BBNJ treaty represents a critical tool for archipelagic nations like the Philippines—not only to influence global marine governance but also to safeguard marine ecosystems, promote fair benefit-sharing, and support the livelihoods of coastal communities reliant on ocean resources.

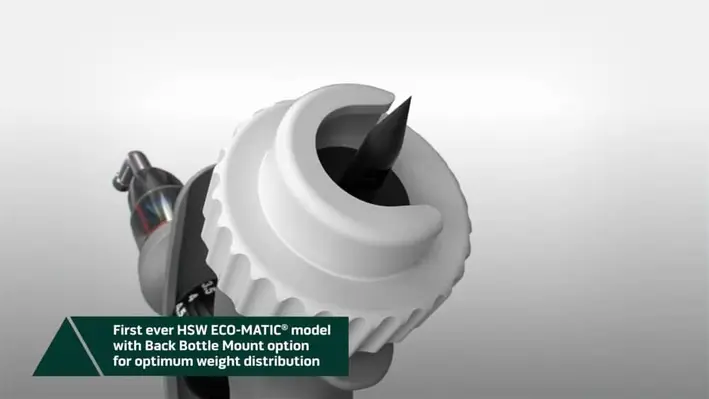

Biobest's Entomatic handheld tool an effective pest management

Biobest has introduced the Entomatic Handheld, a portable mite and insect dispenser engineered to deliver biological pest control with greater precision, flexibility, and user comfort

Developed in collaboration with Hortiworld, this compact, ergonomic device is tailored for confined or irregular growing environments where targeted application is key.

Designed for growers of linear crops such as strawberries, as well as greenhouses, ornamental nurseries, and small-scale or variable-layout operations, the Entomatic Handheld is a game-changer in Integrated Pest Management (IPM).“The unit is designed for focused, even distribution of beneficials such as Phytoseiulus persimilis, Amblyseius cucumeris, Orius laevigatus, and Franklinothrips,” said Sam Gui, market development manager for High Tech IPM at Biobest.

For growers working with Amblyseius swirskii, the unit can simultaneously dispense Nutrimite, Biobest’s supplementary feed, making pest control even more effective. Adjustable rotator and fan speeds allow for application customisation depending on crop type and setting, while a removable hopper lid doubles as a stand - ideal for quick, efficient refills.

The Entomatic Handheld delivers blanket treatments up to three meters wide, perfect for ornamental potted plants. It also features a snout attachment for accurate, row-by-row application in narrow, linear crops. “The vertical slim design makes it easy to turn and walk in tight spaces,” added Gui.

The innovation also boasts lower mite mortality rates compared to other handheld dispensers and supports bulk loose formats, reducing the need for single-use packaging. This highlights Biobest’s focus on sustainable, grower-friendly solutions that not only protect crops but also promote environmentally conscious farming practices.

Whether you’re operating a high-tech glasshouse or a small ornamental nursery, the Entomatic Handheld is designed to help you achieve faster, more efficient, and more precise biological control outcomes.

SoLAR project: revolutionizing agriculture with solar power

The SoLAR project, funded by the Swiss Agency for Development and Cooperation (SDC), is entering its second phase, aiming to deepen agricultural resilience and climate transformation in smallholder farming

Launched by the International Water Management Institute (IWMI), the initiative runs from July 2025 to December 2029 and expands its geographical and thematic focus, now incorporating Ethiopia and Kenya, while continuing its work in Bangladesh, India, Nepal, and Pakistan. Building on the success of its first phase (2019–2024), SoLAR looks to scale solar energy solutions for agriculture and position them as a replicable and scalable model for climate-resilient agriculture across the Global South.

In its first phase, SoLAR focused on generating evidence, piloting innovative financing models, and influencing policy to integrate solar-powered irrigation systems (SIPs). These solar pumps have proven effective in mitigating climate impacts by replacing diesel pumps and promoting sustainable groundwater usage. “Across the four South Asian countries, we have seen promising steps toward scaling solar irrigation sustainably and inclusively,” said Darshini Ravindranath, Project Lead and Research Group Leader at IWMI. The project has helped governments in Bangladesh and India integrate solar irrigation into national strategies, while in Nepal, it led to a significant policy shift, including revised subsidy criteria supporting women farmers and smallholders.

Key outcomes include the promotion of gender-sensitive policies, innovative financing such as micro-financing and grants, and the adoption of solar irrigation systems that reduce carbon emissions, conserve groundwater, and support high-value crops. IWMI’s work also extended to grid-connected solar irrigation in Nepal, enabling farmers to sell surplus energy, providing them with additional income streams while promoting responsible groundwater use.

In phase two, SoLAR will expand its reach to East Africa, focusing on scaling solar-powered solutions for irrigation, cooling, and processing. With Kenya and Ethiopia facing climate and energy challenges, the project sees solar technology as a transformative tool for boosting year-round agricultural production and enhancing food security. Muluken Elias Adamseged, Deputy Country Representative at IWMI in Ethiopia, remarked, “Scaling solar-powered irrigation, cooling, and processing can boost year-round production, cut losses and costs, and enhance food security.”

The second phase aims to drive an integrated approach with evidence-based policy design, accelerated funding for solar adoption, enhanced capacity building, and the establishment of Living Labs to test solar solutions in diverse settings. The program will directly benefit smallholder farmers in India, Bangladesh, Kenya, and Ethiopia by improving water and energy security, reducing emissions, and enhancing resilience to climate risks, according to Philippe Sas, Head of Cooperation for SDC in India.